Feb . 01, 2025 05:13

Back to list

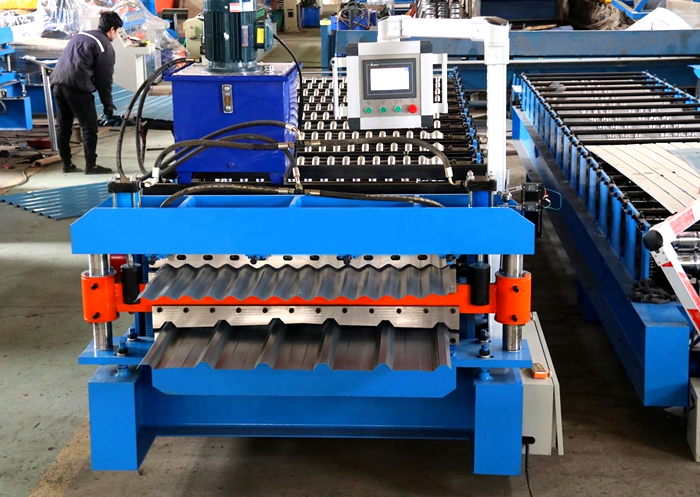

T18 C18 Metal roofing machine Roof sheet forming machine

Finding the right sheet metal roofing machine for sale doesn't have to be a daunting task. Equipped with genuine experience and an understanding of industry needs, choosing the best equipment becomes a calculated investment rather than a simple purchase. As a professional deeply entrenched in the intersection of construction machinery and its transformative impact on modern roofing solutions, it is crucial to ensure that the decision aligns with production demands, efficiency, and long-term sustainability.

Authoritativeness in the market often rests with those who understand the importance of machine footprint and energy consumption. Investing in a machine that optimizes space and offers energy-efficient operations not only reduces operational costs but also speaks to a broader commitment to environmentally conscious practices. This is increasingly critical as sustainability becomes a core focus in construction methodologies globally. Trustworthiness, especially in this niche market, stems from thorough due diligence—both in the selection of machinery and after-sale support. Opt for suppliers with a proven track record of delivering robust machinery and excellent customer service. Customer testimonials, reviews, and detailed product demonstrations provide transparency and bolster confidence in the purchase decision. A reliable warranty and comprehensive training programs are additional layers that solidify a supplier’s credibility. Real-world applications and ongoing customer feedback illuminate the practical benefits of investing in cutting-edge sheet metal roofing machines. Businesses report not only streamlined production processes but also the agility to tackle diverse projects—from residential roofing to large-scale commercial installations. These machines empower teams, providing the confidence to deliver on tight timelines without sacrificing quality or safety. In summary, the process of selecting a sheet metal roofing machine transcends mere transactional engagement—it is about building a partnership with technology that promises precision, reliability, and adaptability. Given the profound impact these machines have on production efficiency and output quality, continually upgrading and aligning with the latest technological trends remains a strategic imperative for any construction business focused on long-term success. As with any critical investment, prioritize features that reflect genuine experience, ensure expertise in handling various materials, demand authoritativeness in efficiency, and cultivate trust through proven supplier support.

Authoritativeness in the market often rests with those who understand the importance of machine footprint and energy consumption. Investing in a machine that optimizes space and offers energy-efficient operations not only reduces operational costs but also speaks to a broader commitment to environmentally conscious practices. This is increasingly critical as sustainability becomes a core focus in construction methodologies globally. Trustworthiness, especially in this niche market, stems from thorough due diligence—both in the selection of machinery and after-sale support. Opt for suppliers with a proven track record of delivering robust machinery and excellent customer service. Customer testimonials, reviews, and detailed product demonstrations provide transparency and bolster confidence in the purchase decision. A reliable warranty and comprehensive training programs are additional layers that solidify a supplier’s credibility. Real-world applications and ongoing customer feedback illuminate the practical benefits of investing in cutting-edge sheet metal roofing machines. Businesses report not only streamlined production processes but also the agility to tackle diverse projects—from residential roofing to large-scale commercial installations. These machines empower teams, providing the confidence to deliver on tight timelines without sacrificing quality or safety. In summary, the process of selecting a sheet metal roofing machine transcends mere transactional engagement—it is about building a partnership with technology that promises precision, reliability, and adaptability. Given the profound impact these machines have on production efficiency and output quality, continually upgrading and aligning with the latest technological trends remains a strategic imperative for any construction business focused on long-term success. As with any critical investment, prioritize features that reflect genuine experience, ensure expertise in handling various materials, demand authoritativeness in efficiency, and cultivate trust through proven supplier support.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products