Top Manufacturers of Sheet Metal Roofing Equipment and Machinery

The Rise of Sheet Metal Roofing Machine Companies

In the ever-evolving construction industry, sheet metal roofing has emerged as a prominent choice for both residential and commercial buildings. This popularity stems from its durability, aesthetic appeal, and energy efficiency. As demand for quality roofing solutions increases, sheet metal roofing machine companies are stepping into the spotlight, providing state-of-the-art machinery that revolutionizes the production and installation of metal roofs.

The Importance of Sheet Metal Roofing

Sheet metal roofing is known for its ability to withstand harsh weather conditions, including high winds, heavy rain, and extreme temperatures. Unlike traditional roofing materials, such as asphalt shingles, sheet metal offers superior longevity, often lasting 40-70 years with minimal maintenance. Moreover, its reflective properties contribute to energy efficiency, helping to lower heating and cooling costs for homeowners and businesses alike.

As the global population continues to grow, so does the need for sustainable and resilient building materials. Sheet metal roofing fits this need perfectly, not only due to its longevity but also because it is often made from recyclable materials, contributing to a more sustainable construction environment.

The Role of Machine Manufacturers

With the rise in popularity of sheet metal roofing, the demand for specialized machinery capable of producing high-quality metal sheets has surged. Sheet metal roofing machine companies have stepped up to the plate, designing and manufacturing machines that streamline the production process. These machines enable contractors to create customized roofing panels tailored to specific project requirements.

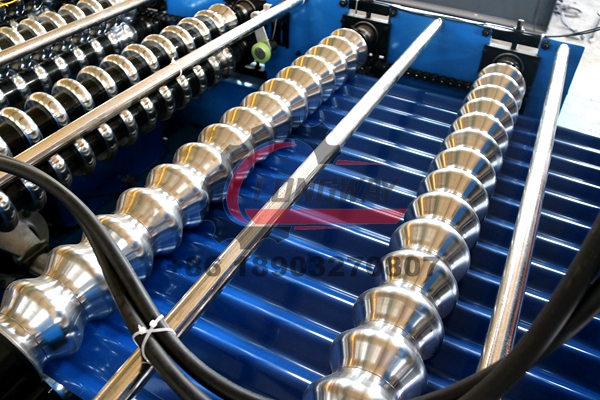

From roll-forming machines that shape metal sheets into desirable profiles to cutting and bending machines that finalize the product, these manufacturers play a crucial role in the roofing supply chain. Additionally, advanced technology, such as computer numerical control (CNC) systems, allows for precision manufacturing, enhancing the overall quality and consistency of roofing materials.

Key Features of Modern Roofing Machines

Modern sheet metal roofing machines incorporate several innovative features that set them apart from traditional equipment

. For instance, many machines now offersheet metal roofing machine companies

1. Automation Automated systems reduce the need for manual labor, minimizing human error and increasing production speed. This is particularly beneficial for large-scale projects that require a high volume of materials.

2. Customizability Advanced machines can quickly switch between different profiles and sizes, allowing manufacturers to meet diverse customer needs without significant downtime.

3. Energy Efficiency Newer machines are designed to consume less energy while maximizing output. This is not only cost-effective for manufacturers but also aligns with the growing focus on sustainable practices in the construction industry.

4. Quality Control Many modern machines are equipped with integrated quality control systems that monitor the production process in real-time, ensuring that any defects are identified and corrected immediately.

The Future of Sheet Metal Roofing Machine Companies

Looking ahead, the future appears bright for sheet metal roofing machine companies. As construction trends shift toward more sustainable building practices and materials, these manufacturers are well-positioned to meet the rising demand. Furthermore, ongoing advancements in technology, such as robotics and artificial intelligence, are set to transform the production landscape, making processes even more efficient and less labor-intensive.

Additionally, increased collaboration between manufacturers, architects, and builders will further enhance the adaptability of sheet metal roofing. By working closely together, all stakeholders can better understand the evolving needs of the industry and develop innovative solutions that drive the market forward.

Conclusion

In conclusion, sheet metal roofing machine companies play an essential role in the modern construction landscape. Their ability to provide advanced machinery that meets the growing demand for high-quality, sustainable roofing solutions underscores their importance in this industry. As we look to the future, the continued innovation and adaptability of these companies will be vital in shaping the next generation of roofing materials, ensuring they remain an integral part of our built environment. With a firm foundation of technology and a commitment to quality, sheet metal roofing machine companies are poised to lead the charge in transforming the roofing industry for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025