sheet metal roll forming machines for sale manufacturer

Sheet Metal Roll Forming Machines for Sale A Comprehensive Guide

In the world of manufacturing, sheet metal roll forming machines play a crucial role in producing components with high precision and efficiency. These machines are widely used in various industries, including automotive, construction, and appliances, to create parts from flat metal sheets through a continuous bending process. As the demand for durable and lightweight materials grows, investing in high-quality roll forming machinery is essential for businesses looking to enhance productivity and reduce costs.

What are Sheet Metal Roll Forming Machines?

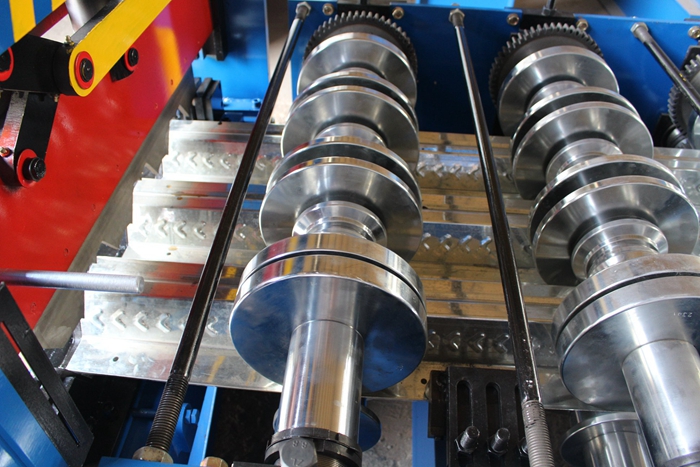

Sheet metal roll forming machines are specialized equipment that transforms flat sheet metal into desired shapes by passing the material through a series of rollers. Each roller is designed to progressively shape the metal, allowing for intricate designs and consistent dimensions. The process begins with a sheet of metal, typically steel or aluminum, which is then fed into the machine, where it undergoes a series of bends as it moves through multiple forming stations.

These machines can produce a wide array of products, including roof panels, metal studs, gutters, and various structural components. The flexibility and adaptability of roll forming machines make them an indispensable tool in modern manufacturing.

Key Features of Roll Forming Machines

When searching for sheet metal roll forming machines for sale, there are several key features to consider

1. Customization Options Many manufacturers offer customizable roll forming machines to cater to specific production needs. This allows businesses to create unique profiles and adjust the machinery to accommodate different materials and thicknesses.

2. Speed and Efficiency High-speed roll forming machines can significantly increase production rates, allowing companies to meet demand more effectively. Look for machines that balance speed with precision to avoid compromising product quality.

3. Durability Machines made from high-grade materials will ensure long-term performance and reduce maintenance costs. Consider factors like frame construction and component quality when evaluating machines.

sheet metal roll forming machines for sale manufacturer

4. Ease of Operation User-friendly controls and automated features make roll forming machines easier to operate, reducing the learning curve for new employees. Advanced models may include computerized controls for enhanced precision and monitoring.

5. Safety Features Safety should always be a top priority. Look for machines equipped with protective covers, emergency stop buttons, and other safety mechanisms to ensure a secure working environment.

Benefits of Using Roll Forming Machines

1. Cost-Effectiveness Once set up, roll forming is an efficient process that requires minimal labor while maximizing material usage. The ability to produce large volumes of parts quickly can lead to significant savings in both time and operational costs.

2. Consistency Roll forming allows for high levels of accuracy, producing uniform products with tight tolerances. This consistency is vital in industries where quality control is paramount.

3. Versatility Roll forming machines can work with a variety of materials and thicknesses, making them suitable for a diverse range of applications. This versatility allows businesses to adapt to changing market demands more smoothly.

4. Enhanced Strength The continuous and cold-forming nature of roll forming enhances the mechanical properties of the metal, resulting in stronger and more durable components.

Finding the Right Machine for Your Business

When considering purchasing sheet metal roll forming machines for sale, it is essential to partner with reputable manufacturers and suppliers. Research the company’s background, read customer reviews, and inquire about warranties and after-sales support. A reliable supplier will help you choose the right machine tailored to your specific requirements, ensuring your investment meets your production goals.

In conclusion, sheet metal roll forming machines are invaluable assets in modern manufacturing, providing efficiency, precision, and versatility. Whether you are looking to expand your production capabilities or improve existing processes, investing in a high-quality roll forming machine can significantly contribute to your business's success. With various options available in the market today, careful consideration and research will help you find the perfect machine to meet your manufacturing needs.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025