sheet metal roll forming machines for sale

Sheet Metal Roll Forming Machines for Sale A Comprehensive Guide

In the rapidly evolving manufacturing landscape, sheet metal roll forming machines have become indispensable tools for producing high-quality metal components with precision and efficiency. These machines are designed to convert flat sheets of metal into various shapes and profiles, catering to a wide array of industries such as construction, automotive, and appliances. If you're in the market for sheet metal roll forming machines, understanding their features, benefits, and available options can significantly enhance your purchasing decision.

What is Sheet Metal Roll Forming?

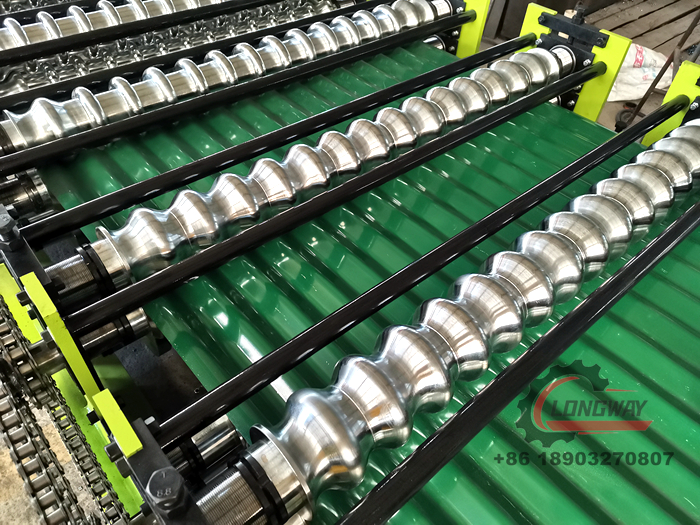

Sheet metal roll forming is a continuous process that involves passing a flat strip of metal through a series of rollers. Each roller gradually bends the metal into the desired shape, allowing for the creation of complex profiles with uniformity and repeatability. The process is typically conducted at room temperature, making it an energy-efficient method for shaping metal.

Advantages of Using Roll Forming Machines

1. High Precision and Consistency Roll forming machines are engineered to deliver precise dimensions and profiles, reducing the likelihood of defects in the finished products. This consistency is crucial in industries where tolerance levels are strict.

2. Cost-Effective Production Once set up, roll forming machines can produce large quantities of parts quickly, lowering the cost per unit. This is particularly advantageous for businesses operating on tight margins.

3. Material Versatility Roll forming can accommodate a wide range of materials, including steel, aluminum, and stainless steel. This flexibility allows manufacturers to choose the best material for their specific application.

4. Minimal Waste Since the process generates minimal scrap material compared to other forming methods, roll forming is an environmentally friendly option that can significantly reduce production costs.

sheet metal roll forming machines for sale

Types of Sheet Metal Roll Forming Machines

1. Standard Roll Forming Machines These are designed for general use and can accommodate a variety of profiles. They are ideal for manufacturers who need flexibility in their production capabilities.

2. Heavy-Duty Roll Forming Machines Specifically built for high-strength materials or thick metal sheets, these machines are constructed with robust components to handle rigorous production demands.

3. Inline Roll Forming Machines In industries where efficiency is paramount, inline machines can integrate with other production systems, allowing for continuous operation and the reduction of man-hours.

4. Portable Roll Forming Machines For on-site applications such as construction or roofing, portable machines offer convenience and versatility, enabling quick adjustments and transportation.

Choosing the Right Roll Forming Machine

When selecting a sheet metal roll forming machine, consider the following factors

- Production Volume Assess your production requirements to determine the machine’s capacity and speed. - Material Thickness Ensure the machine can handle the specific thickness and type of metal you intend to use. - Profile Complexity If you need custom shapes, verify that the machine can accommodate your design needs. - Budget While it's tempting to opt for the lowest-priced option, consider the total cost of ownership, including maintenance and operating costs.

Conclusion

Investing in a sheet metal roll forming machine is a strategic decision that can improve efficiency, product quality, and profitability in your manufacturing processes. By understanding the benefits, types, and key considerations, you can select the right machine that aligns with your business goals. Whether you're a small business looking to streamline operations or a large manufacturer aiming to expand your capabilities, the right roll forming machine can make all the difference in achieving success in the competitive metal fabrication industry. If you're ready to enhance your production capabilities, explore the market for sheet metal roll forming machines for sale to find the perfect fit for your needs.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025