Sheet Roll Forming Machine - High Precision Metal Fabrication Solutions

Understanding Sheet Roll Forming Machines

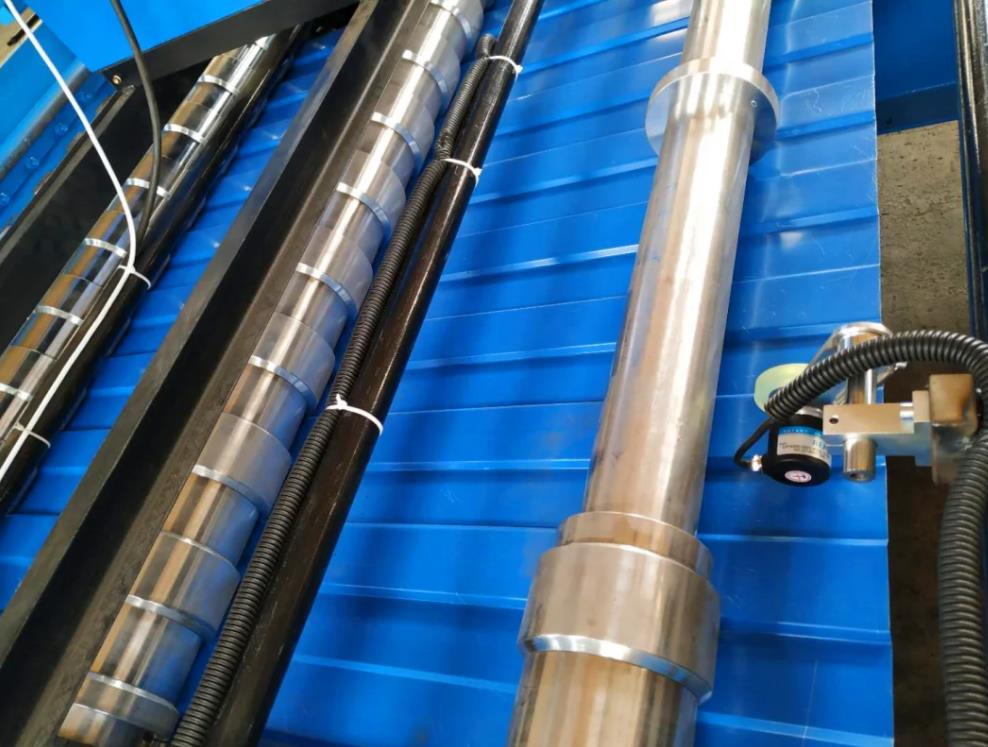

Sheet roll forming is a vital manufacturing process that transforms flat sheets of metal into various shapes and profiles. This technique is widely used in industries such as construction, automotive, and appliance manufacturing, due to its ability to create consistent and durable components efficiently. At the heart of this process is the sheet roll forming machine, a sophisticated piece of equipment that shapes metal sheets through a series of rollers.

A sheet roll forming machine consists of a set of rollers arranged in a particular sequence. The procedure begins with a flat sheet of metal being fed into the machine, which guides it through the rollers. As the metal sheet passes through this series of rollers, it is gradually shaped into a desired profile. This could range from simple shapes like angles and channels to more complex designs such as roofing sheets and structural components. The use of rollers allows manufacturers to achieve precise dimensions and intricate designs at high production rates.

One of the critical advantages of sheet roll forming machines is their efficiency. Unlike traditional methods, which may involve multiple processes or manual labor, roll forming streamlines the production of metal components. Once set up, these machines can produce large volumes of product with minimal operator intervention. This leads to reduced labor costs and faster turnaround times, making it an attractive option for manufacturers looking to optimize their processes.

sheet roll forming machine

Moreover, the material economy in roll forming is noteworthy. The process generates minimal waste, as the metal sheets are used effectively. This not only lowers material costs but also aligns with sustainable manufacturing practices. Additionally, the finished products tend to have better strength-to-weight ratios compared to those created using other methods. This characteristic is particularly appealing in industries where weight savings can lead to performance enhancements, such as automotive manufacturing.

The versatility of sheet roll forming machines is another significant benefit. The same machine can often be adjusted to create different profiles by changing the roller configuration. This adaptability allows manufacturers to respond quickly to varying customer needs, producing custom profiles without the need for a complete retooling of the machine. This capability is invaluable in today’s fast-paced market, where demands can change rapidly.

Furthermore, advancements in technology have greatly enhanced the capabilities of sheet roll forming machines. Modern machines are often equipped with computer numerical control (CNC) systems, enabling precise control over the forming process. This technology allows for enhanced accuracy and repeatability in production, further improving product quality. Additionally, automation and integration with other manufacturing systems can streamline operations, rendering the entire production line more efficient.

In conclusion, sheet roll forming machines play a crucial role in the modern manufacturing landscape. Their efficiency, versatility, and ability to produce high-quality products with minimal waste make them indispensable in various industries. As technology continues to evolve, these machines will likely become even more advanced, offering manufacturers new opportunities to innovate and enhance their processes. Whether it’s for creating roofing panels, structural components, or automotive parts, the impact of sheet roll forming machines on manufacturing is profound and lasting.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025