Jun . 23, 2024 03:15

Back to list

sheet metal roll forming factories

Sheet Metal Roll Forming Factories A Crucial Link in Manufacturing Industry

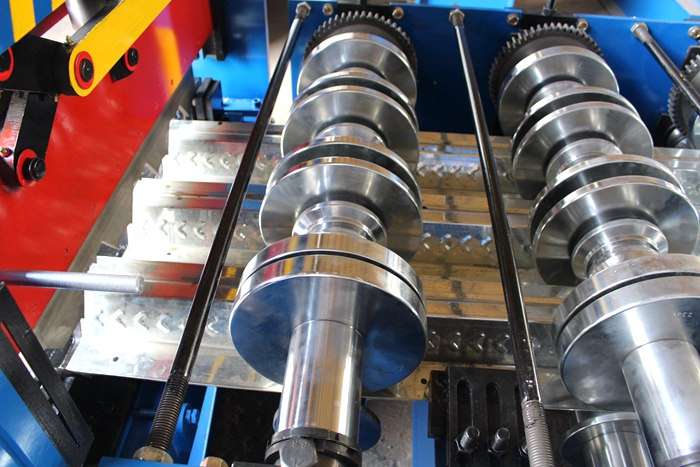

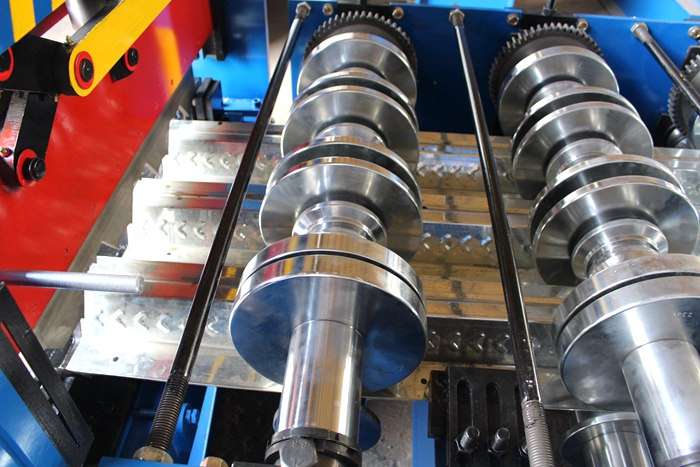

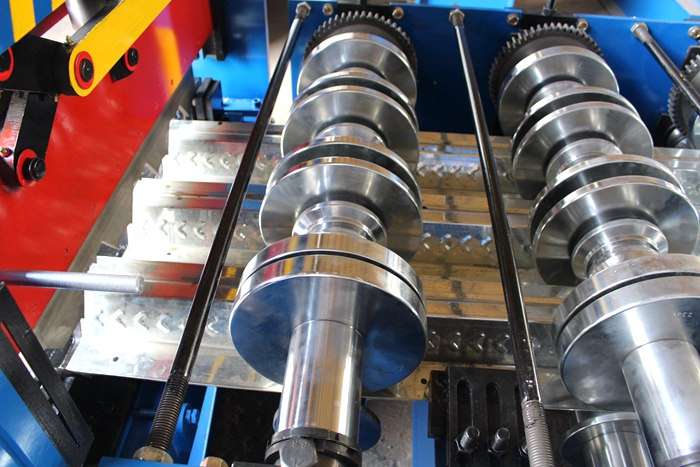

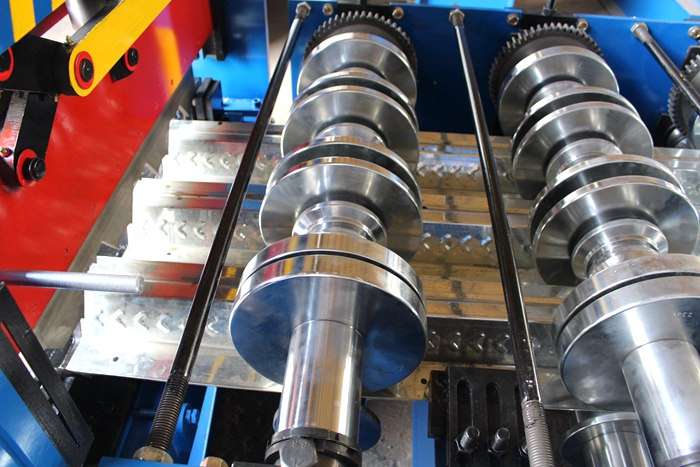

Sheet metal roll forming factories play a vital role in the manufacturing industry, transforming flat sheets of metal into complex shapes and components used in a wide range of applications. These factories utilize advanced machinery and techniques to perform various forming processes, including bending, rolling, punching, and cutting, all in a continuous and efficient manner.

One of the key advantages of sheet metal roll forming is its ability to produce parts with high precision and repeatability. This is achieved through the use of precision-controlled rollers that apply consistent pressure and force to the metal sheet, ensuring that it is formed to the desired shape and size. As a result, these factories are capable of producing parts with tight tolerances and excellent surface finishes, making them ideal for use in demanding applications such as automotive, aerospace, and construction.

Another important aspect of sheet metal roll forming is its versatility. These factories can process a wide variety of metals, including steel, aluminum, copper, and titanium, and can accommodate different thicknesses and gauges. This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery

This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery sheet metal roll forming factories.

In addition to their production capabilities, sheet metal roll forming factories also play a crucial role in reducing material waste and improving efficiency. By using continuous forming processes, these factories are able to minimize the amount of scrap generated during production, resulting in cost savings for their customers. They also employ advanced technologies such as automation and robotics to streamline their operations and improve productivity.

Overall, sheet metal roll forming factories are essential partners for manufacturers seeking to produce high-quality, custom components at competitive prices. Their expertise in metal forming and commitment to innovation make them well-suited to meet the evolving needs of the manufacturing industry. As demand for metal products continues to grow, these factories will remain critical players in the global supply chain, helping to drive progress and drive growth in various sectors.

sheet metal roll forming factories.

In addition to their production capabilities, sheet metal roll forming factories also play a crucial role in reducing material waste and improving efficiency. By using continuous forming processes, these factories are able to minimize the amount of scrap generated during production, resulting in cost savings for their customers. They also employ advanced technologies such as automation and robotics to streamline their operations and improve productivity.

Overall, sheet metal roll forming factories are essential partners for manufacturers seeking to produce high-quality, custom components at competitive prices. Their expertise in metal forming and commitment to innovation make them well-suited to meet the evolving needs of the manufacturing industry. As demand for metal products continues to grow, these factories will remain critical players in the global supply chain, helping to drive progress and drive growth in various sectors.

This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery

This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery This versatility allows them to produce parts for a diverse range of industries, from consumer electronics to heavy machinery sheet metal roll forming factories.

In addition to their production capabilities, sheet metal roll forming factories also play a crucial role in reducing material waste and improving efficiency. By using continuous forming processes, these factories are able to minimize the amount of scrap generated during production, resulting in cost savings for their customers. They also employ advanced technologies such as automation and robotics to streamline their operations and improve productivity.

Overall, sheet metal roll forming factories are essential partners for manufacturers seeking to produce high-quality, custom components at competitive prices. Their expertise in metal forming and commitment to innovation make them well-suited to meet the evolving needs of the manufacturing industry. As demand for metal products continues to grow, these factories will remain critical players in the global supply chain, helping to drive progress and drive growth in various sectors.

sheet metal roll forming factories.

In addition to their production capabilities, sheet metal roll forming factories also play a crucial role in reducing material waste and improving efficiency. By using continuous forming processes, these factories are able to minimize the amount of scrap generated during production, resulting in cost savings for their customers. They also employ advanced technologies such as automation and robotics to streamline their operations and improve productivity.

Overall, sheet metal roll forming factories are essential partners for manufacturers seeking to produce high-quality, custom components at competitive prices. Their expertise in metal forming and commitment to innovation make them well-suited to meet the evolving needs of the manufacturing industry. As demand for metal products continues to grow, these factories will remain critical players in the global supply chain, helping to drive progress and drive growth in various sectors. Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products