Automatic Self-Locking Roof Panel Roll Forming Equipment for Efficient Manufacturing

Self-Lock Roof Panel Roll Forming Machine A Game Changer in Roofing Solutions

In the modern construction industry, efficiency and durability are paramount. The self-lock roof panel roll forming machine has emerged as a revolutionary tool that enhances both the speed and quality of roofing projects. This machine is designed to produce self-locking roof panels, which are increasingly favored for their ease of installation and excellent weather resistance.

The key feature of the self-lock roof panel is its unique locking mechanism that eliminates the need for additional fasteners. This not only speeds up the installation process but also reduces potential points of leakage, making structures more robust against harsh weather conditions. The roll forming machine itself is engineered to deliver consistent high-quality profiles, ensuring that each panel fits perfectly with adjoining panels, enhancing the overall integrity of the roof.

One of the primary advantages of utilizing a self-lock roof panel roll forming machine is its versatility. It can produce panels in various widths, lengths, and thicknesses, tailored to meet specific project needs. This customization capability allows builders to optimize material usage, thereby minimizing waste and reducing overall costs. Moreover, advanced technology enables the machine to operate at high speeds without compromising precision, making it an invaluable asset for both large-scale construction projects and smaller-scale installations.

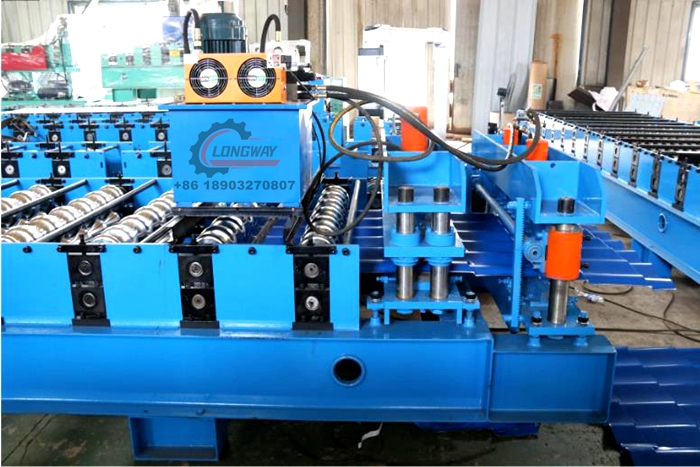

self lock roof panel roll forming machine

Furthermore, the machine’s automated features significantly improve the production workflow. Operators can set parameters and monitor the process in real-time, ensuring a smooth operation that boosts productivity. Safety is another critical aspect; modern machines are equipped with safeguards to protect workers and reduce the risk of accidents during operation.

In addition to its practical applications, self-lock roof panels contribute to sustainability. Many of these panels are made from recyclable materials and have energy-efficient properties, helping to meet modern green building standards. This aligns with the industry's shift towards more sustainable practices and eco-friendly solutions.

In conclusion, the self-lock roof panel roll forming machine stands at the forefront of roofing technology. With its efficiency, cost-effectiveness, and environmentally friendly benefits, it is poised to become a standard in roofing applications. As the construction industry continues to evolve, embracing such innovations will be essential for meeting the demands of both builders and consumers alike.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025