sandwich panel roll forming machine manufacturers

The Rise of Sandwich Panel Roll Forming Machine Manufacturers

In the modern construction industry, the demand for efficient, cost-effective, and sustainable building materials has led to the increasing popularity of sandwich panels. These panels, composed of two outer layers and an insulating core, offer exceptional thermal insulation, structural integrity, and lightweight properties. This shift in preferences has propelled the growth of sandwich panel roll forming machine manufacturers, who play a crucial role in producing these innovative materials.

What is a Sandwich Panel?

Before delving into the role of manufacturers, it’s important to understand what sandwich panels are. Typically constructed from a variety of materials such as steel, aluminum, or fiberglass, sandwich panels consist of two thin outer skins enclosing a core material, which can be made of polystyrene, polyurethane, or mineral wool. This unique design not only provides high insulation values but also helps to reduce energy costs and improve indoor comfort. Sandwich panels are widely used in a variety of applications, including industrial buildings, warehouses, cold storage facilities, and even residential structures.

The Technology Behind Roll Forming Machines

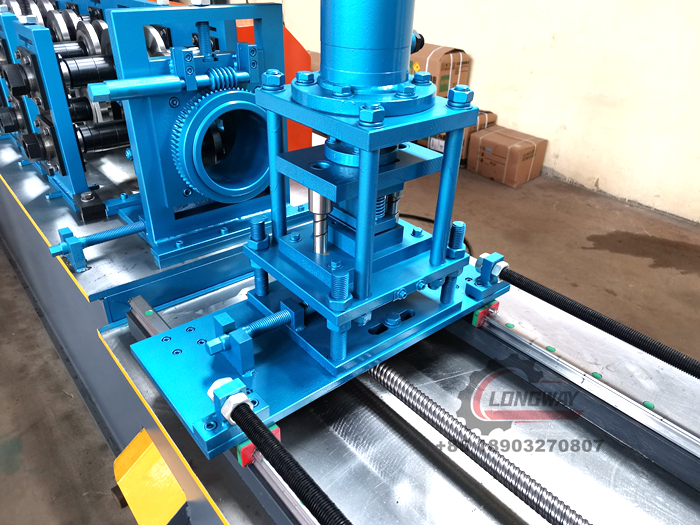

Sandwich panel roll forming machines are specialized equipment designed to create these panels through a highly automated process. The roll forming machine operates by feeding raw material into a series of rollers that gradually shape it into the desired profile while simultaneously applying the core material between the two outer layers. The precision of this process ensures that each panel meets strict quality standards, which is critically important in the building sector.

These machines not only enhance the efficiency of production but also reduce waste, contributing to more sustainable manufacturing practices. Manufacturers can produce panels quickly and in varying lengths, providing flexibility to meet specific project requirements.

Market Trends and Demand

sandwich panel roll forming machine manufacturers

The growth of the sandwich panel market is driven by various factors, including increased construction activities, especially in emerging economies, and a rising focus on energy-efficient building materials. Companies and individuals are keen on investing in materials that not only meet functional needs but also contribute positively to the environment.

As a result, sandwich panel roll forming machine manufacturers are adapting to these market demands by incorporating advanced technologies. Features like smart automation, real-time monitoring, and energy efficiency have become key selling points. The integration of Industry 4.0 concepts, such as IoT (Internet of Things), into the manufacturing process allows for better tracking and optimization, further enhancing product quality and production speed.

Challenges Facing Manufacturers

Despite the promising growth landscape, sandwich panel roll forming machine manufacturers face several challenges. The competition is intensifying, with several players entering the market. This has led to price pressures and the need for manufacturers to continuously innovate and improve their offerings. Moreover, fluctuations in raw material prices can affect production costs and profit margins.

Additionally, manufacturers need to stay ahead of evolving industry standards, regulations, and consumer preferences. Sustainability is at the forefront of construction trends, and manufacturers must be prepared to adapt their processes and materials accordingly.

Conclusion

The sandwich panel roll forming machine manufacturing sector is a dynamic and vital component of the modern construction industry. As the demand for sandwich panels continues to rise, manufacturers must not only respond to market needs but also embrace technological advancements and sustainable practices. By doing so, they can ensure their competitiveness in a rapidly changing environment while contributing to the development of efficient and environmentally friendly building materials. As we look to the future, the role of these manufacturers will undoubtedly expand, driving innovation and quality in construction practices worldwide.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025