sandwich panel roll forming machine manufacturer

The Rise of Sandwich Panel Roll Forming Machine Manufacturers

In the modern construction industry, efficiency, durability, and insulation are paramount. To meet these needs, sandwich panels have become increasingly popular due to their excellent thermal performance and structural integrity. Central to the production of these panels is the sandwich panel roll forming machine, an innovation that has transformed how manufacturers produce building materials. This article explores the significance of sandwich panel roll forming machine manufacturers, their technology, and the benefits they offer to the construction sector.

Understanding Sandwich Panels

Sandwich panels typically consist of two outer layers, often made of metal, and a core material that could be made from polyurethane, polystyrene, or mineral wool. This construction provides superior insulation properties while maintaining a lightweight structure. These panels are used in a variety of applications, including industrial buildings, warehouses, and even residential projects. The demand for such panels has led to a rise in manufacturers specializing in roll forming machinery.

Role of Sandwich Panel Roll Forming Machines

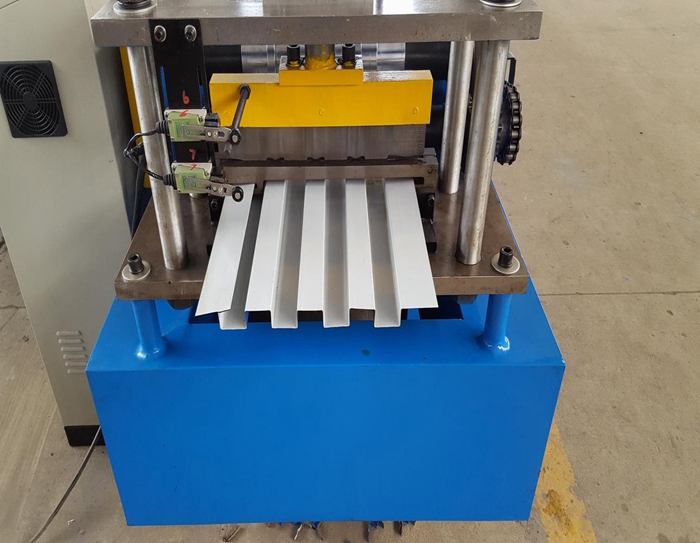

Sandwich panel roll forming machines are specialized equipment that creates the precise shapes and structures needed for sandwich panels. These machines operate by shaping metal sheets into specific profiles that are subsequently combined with insulation material to form a complete panel. The process is continuous, allowing for high production rates with minimal waste, making it economically advantageous for manufacturers.

These machines often come equipped with advanced technologies, including computer numerical control (CNC) systems, which enhance accuracy and reduce labor costs. Additionally, some manufacturers offer fully automated solutions, enabling seamless integration into existing production lines.

Benefits of Partnering with Manufacturers

sandwich panel roll forming machine manufacturer

1. Cost-Effectiveness By investing in high-quality sandwich panel roll forming machines from reputable manufacturers, businesses can significantly lower their production costs. The efficiency of these machines allows for faster production times and reduced labor costs.

2. Customization Leading manufacturers often provide customizable solutions tailored to specific client needs. This includes the ability to create panels of varying thicknesses, lengths, and profiles, which can cater to diverse construction requirements.

3. Quality Assurance When sourcing machinery from established manufacturers, companies can expect superior quality and durability. Many manufacturers adhere to stringent quality control measures, ensuring that their machines are reliable and capable of producing high-quality panels consistently.

4. Technical Support and Training Many sandwich panel roll forming machine manufacturers provide extensive technical support and training for their clients. This assistance is invaluable, especially for businesses new to panel production, as it helps streamline operations and maximize the machines' potential.

5. Innovation and Technology Updates The construction industry is constantly evolving, and manufacturers keep pace by incorporating the latest technologies into their machines. This commitment to innovation ensures that businesses utilizing these machines remain competitive in a dynamic market.

Conclusion

The importance of sandwich panel roll forming machine manufacturers cannot be overstated in today’s construction landscape. By providing advanced machinery that meets the growing demand for energy-efficient and structurally sound building materials, these manufacturers play a critical role in shaping the future of construction. Their focus on innovation, quality, and customer service enables businesses to thrive in a competitive environment. As the construction sector continues to adapt to new technologies and sustainability practices, the reliance on specialized manufacturers will undoubtedly grow, making it essential for companies to establish strong partnerships in this field.

In summary, investing in sandwich panel roll forming machines is not merely a choice but a strategic necessity for businesses looking to excel in modern construction. By leveraging the capabilities offered by reputable manufacturers, companies can enhance productivity, improve product quality, and ultimately increase their market share in a rapidly evolving industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025