sandwich panel roll forming machine factories

Understanding Sandwich Panel Roll Forming Machine Factories

In the ever-evolving construction industry, efficiency, durability, and cost-effectiveness are vital considerations. One of the revolutionary innovations that have gained prominence in recent years is the sandwich panel roll forming machine. These machines are not merely tools; they represent a significant advancement in manufacturing technology that can drastically change the way buildings are constructed.

A sandwich panel is composed of two outer layers and an insulating core in between. This design provides superior insulation and strength while maintaining a lightweight profile. The roll forming machine plays a crucial role in the production of these panels, enabling factories to fabricate them in varying dimensions and specifications tailored to specific project needs. The essence of manufacturing involves transforming raw materials into finished products, and roll forming machines streamline this process for sandwich panels.

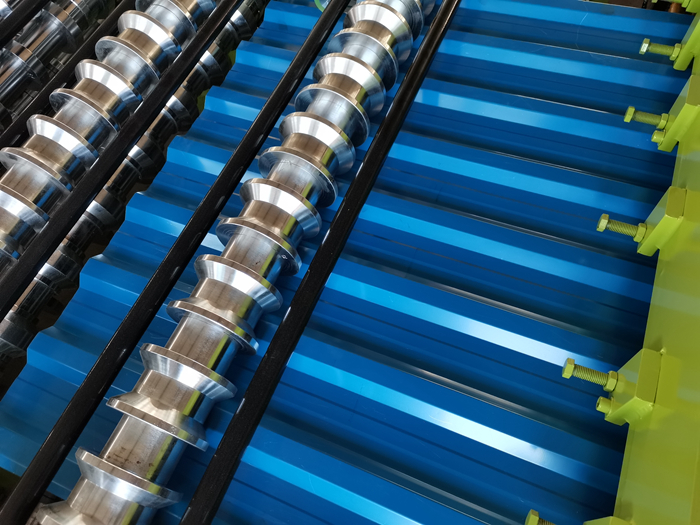

The operation of a sandwich panel roll forming machine begins with the feeding of raw materials, usually steel or aluminum, into the machine. The materials are then shaped through a series of rollers that progressively bend, cut, and form the pieces into panels. This continuous process not only enhances productivity but also reduces material wastage, making it more environmentally friendly. For factory owners, this efficiency translates to lower operational costs, which is critical in a competitive market.

Apart from financial efficiency, the quality of the sandwich panels produced is also paramount. Sandwich panel roll forming machines are engineered to ensure high precision in the manufacturing process. Advanced machinery can achieve tight tolerances, producing panels that meet industry standards for durability and insulation. This attention to quality is essential, as sandwich panels are commonly used in industrial buildings, warehouses, and even residential constructions. Their performance can significantly affect the energy efficiency of a building, reducing heating and cooling costs for end-users.

sandwich panel roll forming machine factories

Another noteworthy aspect of sandwich panel roll forming machine factories is the ability to customize products. The flexibility of modern roll forming technology allows for the production of panels in different styles, colors, and finishes. This customization appeals to architects and builders who aim to create unique and aesthetically pleasing structures. By offering a range of design options, manufacturers can access diverse market segments, further enhancing their competitive edge.

In addition, the automation of the roll forming process cannot be overlooked. Many factories have incorporated advanced technological solutions, such as computer numerical control (CNC) systems, to manage production. Automation not only enhances speed but also reduces human error, leading to higher consistency in product quality. As factories invest in these automated systems, they can scale their operations more significantly, meeting rising global demands while maintaining a high standard of manufacturing.

Furthermore, the growth of global construction trends emphasizes sustainability, and sandwich panel roll forming machine factories are adapting to this shift. The materials used in sandwich panels are often recyclable, and the efficient manufacturing methodologies reduce overall waste. This aligns with the broader push towards sustainable building practices, appealing to environmentally conscious consumers and organizations.

Finally, as the construction industry continues to embrace modern technologies, the role of sandwich panel roll forming machine factories will likely expand. Innovations such as integrating artificial intelligence for predictive maintenance or enhancing supply chain logistics can lead to further efficiencies and new opportunities. Factories that stay ahead of these trends will not only survive but thrive in the fast-paced construction market.

In conclusion, sandwich panel roll forming machine factories represent a key intersection of technology, craftsmanship, and sustainability in modern construction. Their ability to produce high-quality insulated panels efficiently and cost-effectively positions them as invaluable assets in the quest for innovative building solutions. As industries evolve, these factories will undoubtedly play a pivotal role in shaping the future of construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025