Russia market C8 Roof profile forming machine: CE & fast?

C8 roofing, Russian winters, and a machine that just keeps going

In jobsite trailers from Vyborg to Vladivostok, crews keep asking for the same workhorse: the Russia market C8 Roof profile forming machine. To be honest, the momentum makes sense. Russia’s corrugated C8 sheet demand has inched up with warehouse and agricultural builds, and contractors want machines that switch coils fast, hit GOST dimensions, and don’t flinch at -20°C starts. This unit, built in SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE, has quietly become a bit of a staple.

Industry trend snapshot

C8 (≈8 mm rib height) keeps winning for low-rise roofs and fencing—cheap, light, easy to stack. Many customers say they moved away from imported sheets to local forming for cost control and lead-time sanity. Actually, with EAC compliance becoming routine and coils priced in rubles, in-house roll forming is now mainstream.

Process flow and materials

- Decoiling (manual or hydraulic) → leveling → roll forming (12–16 stations, depending on rib fidelity) → length control (encoder) → hydraulic cut → run-out table/stacker.

- Materials: galvanized steel (GOST 14918), pre-painted PPGI, or AZ-coated (≈0.3–0.7 mm). Real-world sweet spot: 0.45–0.55 mm for roofing.

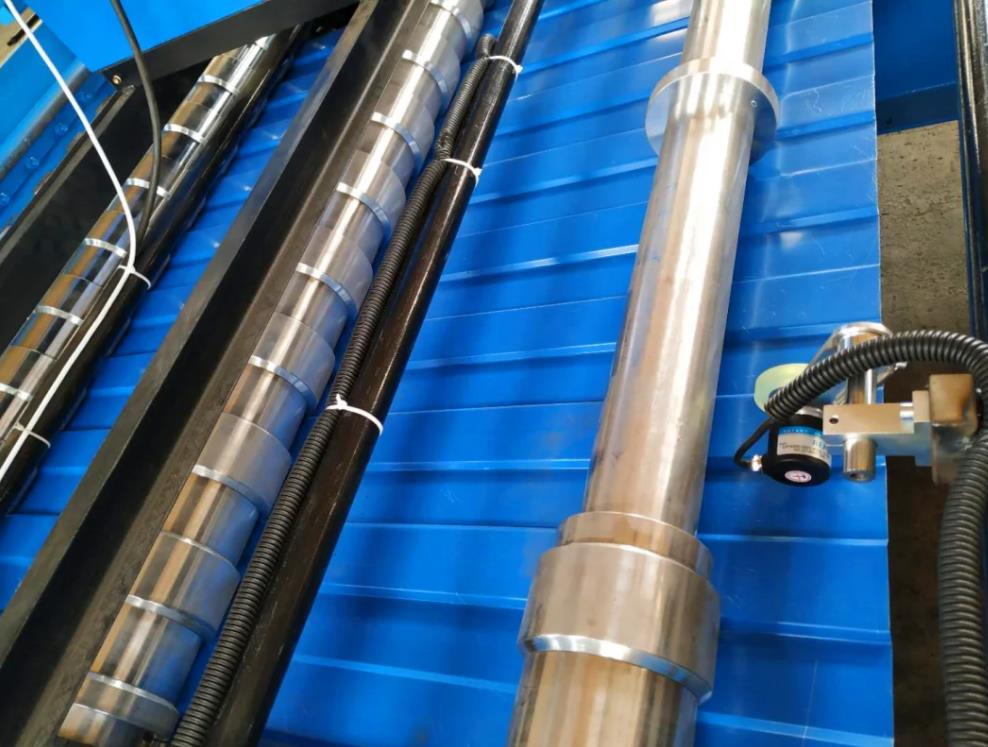

- Methods: roll tooling in 42CrMo, quenched and ground; side frames stress-relieved; shafts ≈φ70 mm (varies by vendor) to reduce deflection on thin gauges.

- Testing standards: profile geometry to GOST 24045; zinc layer per GOST 14918 / ASTM A653 equivalents; electrical safety per EAC TR CU 004/020; factory QA typically ISO 9001.

- Service life: around 10–15 years with basic maintenance; rollers last longer if coils are clean and operators avoid dry runs.

- Industries: roofing, wall cladding, farm sheds, fencing, temporary site enclosures.

Key specs at a glance

| Parameter | Typical value (≈, varies by build) |

|---|---|

| Profile | C8 corrugated, rib height ≈8 mm, pitch ≈115–120 mm |

| Material thickness | 0.3–0.7 mm (best finish around 0.45–0.55 mm) |

| Coil width | 1000–1250 mm |

| Line speed | ≈12–18 m/min (depends on cut length and coating) |

| Drive / hydraulics | Main motor ≈7.5–11 kW; hydraulic ≈4–5.5 kW |

| Control | PLC + HMI, encoder length control, batch counting |

| Certifications | ISO 9001, CE (on request), EAC-ready docs |

The manufacturer notes: C8 roll former customized profile design acceptable. I’ve seen teams request deeper cap overlaps for windy sites and get it within two weeks.

Vendor comparison (pragmatic view)

| Vendor | Pros | Cons |

|---|---|---|

| LWM (China) | Balanced price/speed; C8 tooling matured; fast spares; customization friendly | Lead time spikes in peak season |

| Local fabricator (RU) | On-site support; EAC paperwork straightforward | Higher CAPEX; mixed roller hardness quality |

| EU supplier | Top-tier automation; traceable steel for rollers | Premium pricing; longer import process |

Real jobs, real feedback

Tatarstan, 2024: a mid-sized metal shop swapped to Russia market C8 Roof profile forming machine with a 5-ton hydraulic decoiler. Output rose from ≈2.5 t/day to ≈4 t/day at 0.5 mm PPGI. Geometry checks vs GOST 24045 were within ±0.5 mm on rib pitch—solid for roofing. An installer in Novosibirsk told me the encoder stayed accurate in cold starts after they sheltered the control cabinet. Small detail, big difference.

Maintenance notes: keep zinc dust off the rollers; re-lube weekly; check chain tension monthly. Surprisingly, most stoppages I hear about are dull blades—change them before burrs appear.

Why teams pick it

- Consistent C8 geometry for roofs and fences, compliant with local norms.

- Reasonable speed, easy operator training, and parts availability.

- Customization: non-standard coil widths, embossing, color-mark printers, and stackers.

Standards and references: GOST 24045 (profiles), GOST 14918 (galv. sheet), ASTM A653 (zinc coated), ISO 9001 (QA), EAC/TR CU (safety). Always verify current revisions—specs evolve.

Citations

- GOST 24045 corrugated metal sheet standard (profile geometry)

- GOST 14918 galvanized steel sheet (coating classes)

- ASTM A653/A653M Zinc-Coated (Galvanized) Steel Sheet

- ISO 9001:2015 Quality Management Systems

- EAC/TR CU 004/020 Technical Regulations (low-voltage & EMC)

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025