r panel machine for sale manufacturers

Exploring R Panel Machines for Sale A Look at Manufacturers and Their Offerings

In the modern manufacturing world, efficiency and precision are paramount. One of the standout machines in this domain is the R panel machine, which plays a crucial role in the production of steel panels used in various construction and industrial applications. As the demand for durable and cost-effective building materials grows, many manufacturers are stepping up to meet this need by offering high-quality R panel machines for sale.

What is an R Panel Machine?

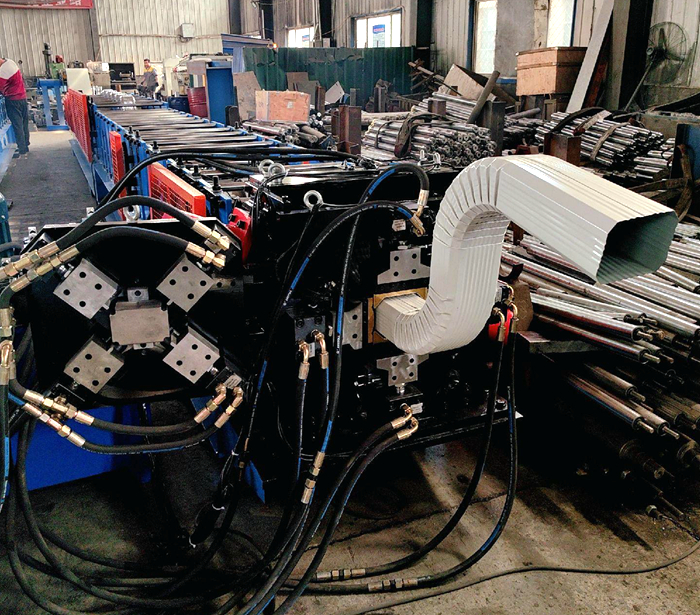

An R panel machine is a specialized piece of equipment designed to manufacture R panels—corrugated metal sheets characterized by their ribbed design. These panels are commonly used in roofs and walls for commercial buildings, warehouses, and agricultural structures due to their strength, lightweight nature, and resistance to weather. The ability to produce these panels efficiently can significantly impact production costs and project timelines.

Manufacturers of R Panel Machines

A number of manufacturers worldwide are known for producing reliable R panel machines. These manufacturers often offer a range of models to cater to different production needs, sizes, and budgets. Companies such as Metform, Roll Forming Machine, and Bradbury Group have established themselves as leaders in the industry, providing machines that are not only efficient but also incorporate the latest technology.

r panel machine for sale manufacturers

When looking for R panel machines for sale, it is essential to consider various factors, including the machine's production capacity, automation features, and ease of maintenance. High-quality machines come equipped with advanced control systems, ensuring that operators can produce panels with precision and consistency.

Benefits of Investing in R Panel Machines

Investing in an R panel machine presents several advantages. First and foremost, it enhances production efficiency. Automated machines reduce manual labor, thereby minimizing errors and increasing throughput. Additionally, R panels produced by these machines typically have superior strength and durability, appealing to customers who prioritize quality.

Furthermore, owning a machine rather than outsourcing production can lead to significant cost savings in the long run. Companies can control their production schedules and reduce lead times, providing them with a competitive edge in the market. The versatility of R panels also means that manufacturers can diversify their product offerings, catering to a broader range of clients and projects.

Conclusion

In conclusion, the demand for R panel machines for sale is on the rise, driven by the need for efficient and durable construction materials. As manufacturers continue to invest in technology and innovation, it becomes essential for businesses looking to expand their capabilities to explore these options. Choosing the right R panel machine can lead to enhanced productivity, lower operating costs, and improved product quality, making it a valuable addition to any manufacturing line. As you consider your options, take the time to research reputable manufacturers and assess their offerings to find the right fit for your needs.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025