R Panel Machine Manufacturing Process and Equipment Overview

The R Panel Machine Factory Revolutionizing the Panel Production Industry

In the ever-evolving world of manufacturing, efficiency, quality, and innovation are paramount. Among the key players propelling this transformation is the R panel machine factory, which stands out as a beacon of technological advancement in the panel production sector. This article delves into the significance of R panel machines, their manufacturing processes, and their impact on the industry.

Understanding R Panel Machines

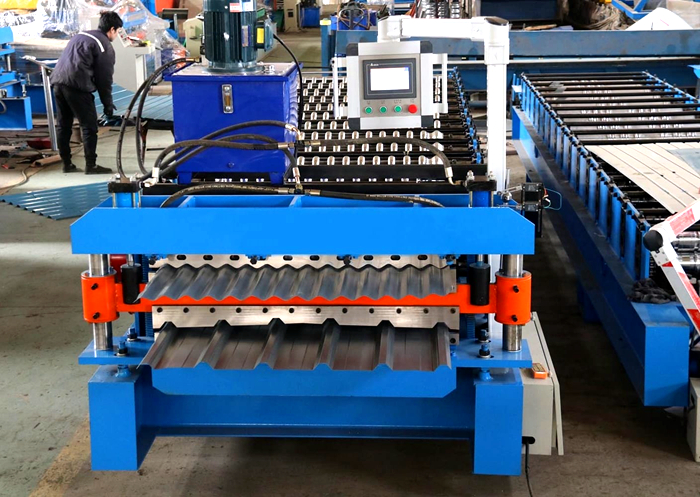

R panel machines are advanced manufacturing systems designed specifically for the production of high-quality panels used in various industries, including construction, furniture, and automotive. These machines automate the panel-making process, ensuring precision, speed, and consistency. The term “R ” refers to a particular model or technology utilized within the machine design, known for its robustness and flexibility in production capabilities.

Streamlining Production Processes

One of the primary advantages of the R panel machine factory is its ability to streamline production processes. Traditional panel manufacturing often involves multiple manual processes, leading to higher labor costs, inefficiencies, and potential errors. In contrast, R panel machines are equipped with state-of-the-art technology that automates cutting, shaping, and finishing processes. This automation not only reduces the time taken to produce panels but also enhances product uniformity.

The factory incorporates advanced computer numerical control (CNC) systems that allow for precise machining. Operators can program the machines to produce various panel designs with just a few clicks. This flexibility is essential in today’s market, where customization is increasingly important. Manufacturers can meet specific client needs without compromising production speed or quality.

Commitment to Quality

Quality assurance is a cornerstone of the R panel machine factory. The factory utilizes high-grade materials and adheres to international standards in panel production. Rigorous quality control measures are in place, including regular inspections and testing of the panels produced, ensuring that they meet the required specifications. This focus on quality not only reduces waste and rework but also enhances customer satisfaction, leading to stronger brand loyalty and repeat business.

r panel machine factory

Environmental Sustainability

In a time when climate change and environmental sustainability are at the forefront of global concerns, the R panel machine factory is committed to minimizing its ecological footprint. The factory implements environmentally friendly practices that contribute to sustainable manufacturing. This includes using renewable energy sources, recycling waste materials, and reducing water consumption during the production process.

Furthermore, the panels produced by R machines are often designed for energy efficiency, which resonates with the growing demand for green building materials. Many of the panels manufactured are compliant with eco-friendly certifications, appealing to environmentally conscious consumers and businesses alike.

Workforce Empowerment and Training

While automation is a significant aspect of the R panel machine factory, the human element remains crucial. The factory prioritizes workforce training and empowerment, ensuring that employees possess the necessary skills to operate advanced machinery and maintain high production standards. Regular training programs are initiated to keep the workforce updated with the latest technologies and manufacturing practices.

By investing in its employees, the R panel machine factory not only boosts morale but also enhances productivity. Empowered employees are more likely to take ownership of their work, leading to a culture of continuous improvement and innovation within the factory.

Conclusion

The R panel machine factory is at the forefront of revolutionizing the panel production industry. With its commitment to efficiency, quality, sustainability, and workforce development, it sets a benchmark for other manufacturers. In an era where the demand for high-quality, customizable products is soaring, the R panel machine factory stands ready to meet the challenges of the future, delivering panels that not only satisfy clients but also contribute to a sustainable and efficient manufacturing landscape. The future of panel production is bright, and the R panel machine factory is leading the way.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025