roof truss press machine factories

Understanding Roof Truss Press Machine Factories

In the world of construction and manufacturing, efficiency and precision are paramount. One of the vital components that enhance these qualities is the roof truss press machine. As the construction industry evolves, the demand for roof truss press machine factories has surged, driven by the need for lightweight yet sturdy structures. This article delves into the significance, functioning, and benefits of these factories in the realm of construction.

What is a Roof Truss Press Machine?

A roof truss press machine is a specialized piece of equipment designed to produce roof trusses, which are pre-engineered frameworks used to support a roof. These trusses are typically made from timber or metal and are used in residential, commercial, and industrial buildings. The primary function of a roof truss press machine is to facilitate the efficient assembly of these structural components, ensuring they meet the necessary design specifications and durability requirements.

The Working Mechanism

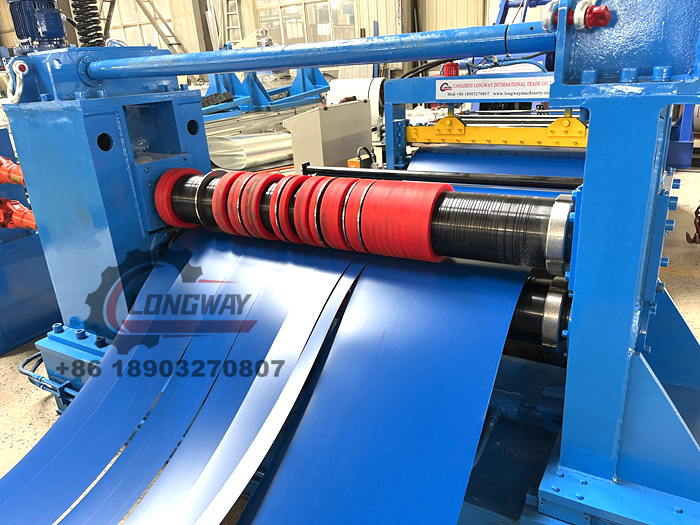

The operation of a roof truss press machine combines a series of hydraulic and mechanical processes. The machine typically consists of a press that holds, shapes, and joins various materials under immense pressure. It is equipped with a series of jigs and fixtures that align the components accurately. By utilizing advanced hydraulic systems, these machines can exert significant force to join materials, ensuring a strong bond that can withstand the test of time.

The manufacturing process begins by preparing the individual components – timber or metal pieces cut to the required dimensions. These pieces are then placed on the machine, where the press applies substantial pressure, using either glue or mechanical fasteners to assemble the truss. This automated process not only guarantees precision but also drastically reduces labor costs and time.

Advantages of Roof Truss Press Machine Factories

1. Increased Efficiency Traditional methods of building roof trusses can be labor-intensive and time-consuming. Roof truss press machines streamline this process, allowing factories to produce large quantities in a fraction of the time. This efficiency enables builders to complete projects more rapidly, meeting tight deadlines.

roof truss press machine factories

2. Cost-Effectiveness By automating the truss production process, factories can significantly reduce labor costs. The machinery requires fewer operators than manual methods, lowering overall production expenses. Additionally, by minimizing material waste due to precise cuts and joints, factories save on raw material costs.

3. Consistency and Quality Roof truss press machines provide a level of precision that is difficult to achieve through manual processes. This consistency in quality ensures that each truss produced meets stringent industry standards and performs reliably. As a result, builders can trust that the structure they are working with is safe and structurally sound.

4. Customization Modern roof truss press machines allow for customization based on specific project needs. Factories can adapt the production process to create trusses of various sizes, shapes, and materials, catering to the unique demands of each construction project.

5. Sustainability With growing awareness about environmental impacts, many factories utilize eco-friendly materials and energy-efficient processes. Roof truss press machines can function with minimal waste and reduced energy consumption, contributing to a greener construction industry.

The Future of Roof Truss Press Machine Factories

As technology continues to advance, the future of roof truss press machine factories looks promising. Innovations such as artificial intelligence and automation are set to enhance production capabilities even further. This evolution will not only improve efficiency but also introduce smarter manufacturing processes that can predict maintenance needs, ensuring minimal downtime.

Furthermore, the push for sustainable building practices will likely drive the demand for advanced roof truss press machines. Factories that prioritize eco-friendly methods and materials will stand out in a competitive market, attracting environmentally-conscious builders.

Conclusion

In conclusion, roof truss press machine factories play a pivotal role in modern construction. By combining efficiency, cost-effectiveness, and quality, they revolutionize the way roof trusses are produced. As the construction industry continues to grow and innovate, these factories will remain at the forefront, shaping the future of building practices and contributing to sustainable development. With ongoing advancements in technology, the roof truss press machine remains an indispensable tool in the quest for superior construction solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025