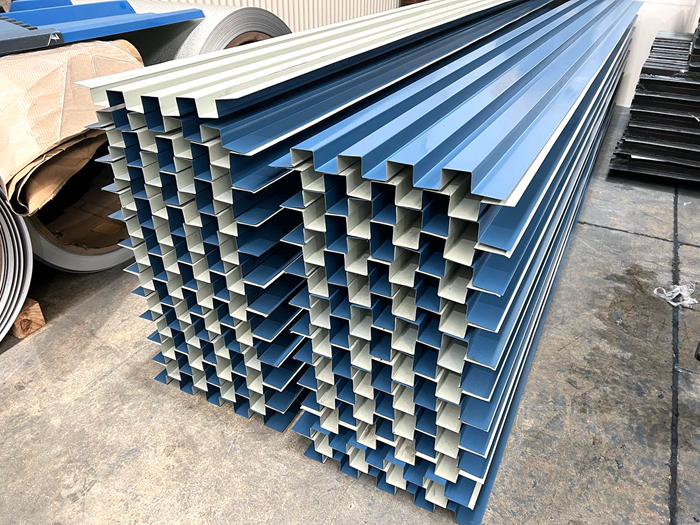

roof truss machinery manufacturer

The Importance of Roof Truss Machinery Manufacturers in Construction

In the ever-evolving world of construction, efficiency and precision are paramount. One of the critical components that enable construction projects to meet their deadlines and maintain high-quality standards is the use of roof trusses. These structural framework systems are essential in supporting roofs and ensuring the stability of buildings. The manufacturers of roof truss machinery play a fundamental role in the construction industry, providing the tools and technologies necessary for the rapid production of roof trusses.

What Are Roof Truss Machinery Manufacturers?

Roof truss machinery manufacturers specialize in producing equipment that facilitates the design, cutting, assembling, and finishing of roof trusses. This machinery includes CNC (Computer Numerical Control) machines, automated truss assembly systems, and various cutting and fastening tools. By leveraging advanced technology, these manufacturers can produce trusses that are not only precise but also customizable to meet various architectural needs.

The Role of Technology in Truss Manufacturing

Advancements in technology have revolutionized the manufacturing processes of roof trusses. Modern machines are equipped with software that allows for intricate design capabilities, ensuring that each truss is made to exact specifications. Using CAD (Computer-Aided Design) programs, architects and engineers can create complex designs that are easily translated into physical structures.

Additionally, automation has significantly increased production speed and reduced labor costs. The use of automated truss assembly machines means that fewer workers are needed on the floor, which leads to lower operational costs while improving safety and efficiency. This high level of automation not only speeds up the production process but also minimizes human error, resulting in higher-quality products.

Benefits of Using Roof Truss Machinery

roof truss machinery manufacturer

The benefits of using machinery in roof truss production are numerous. First and foremost, it allows for rapid scaling of production. In large-scale construction projects where timelines are critical, having the capability to produce a high volume of trusses quickly is invaluable.

Furthermore, the precision offered by modern truss machinery ensures that each piece manufactured fits perfectly into its designated space. This precision is crucial for the structural integrity of the building, as misaligned or incorrectly sized trusses can lead to significant issues down the line, including safety hazards and increased costs due to repairs.

Advancements in Sustainability

Another significant trend among roof truss machinery manufacturers is the shift towards sustainability. Many companies are investing in machinery that uses eco-friendly materials and processes, aligning with the global push for greener building practices. This includes utilizing sustainable wood sources and producing trusses that contribute to energy-efficient building designs.

Moreover, manufacturers are also adopting practices to reduce waste during the production process. This not only benefits the environment but also aids construction companies in lowering costs associated with materials.

Conclusion

In conclusion, roof truss machinery manufacturers are a backbone of modern construction methods. Their advanced machinery and technology streamline the production of roof trusses, ensuring that projects are completed efficiently while adhering to high-quality standards. As the industry continues to evolve, the importance of these manufacturers will only grow, particularly as buildings become more complex and the demand for sustainable practices increases. By investing in innovative machinery, these manufacturers help pave the way for faster, safer, and more sustainable construction practices in the future. The collaboration between architects, builders, and machinery manufacturers is essential for creating structures that are not only functional but also environmentally responsible.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025