roof sheet rolling machine factory

Roof Sheet Rolling Machine Factory An Essential Player in Modern Construction

In the dynamic world of construction and manufacturing, roof sheet rolling machines stand as pivotal equipment that enhances the efficiency and effectiveness of producing roofing materials. As the demand for innovative building solutions grows, factories that specialize in the production of roof sheet rolling machines are at the forefront of this industry revolution. This article delves into the significance, functionality, and market trends surrounding roof sheet rolling machine factories.

Understanding Roof Sheet Rolling Machines

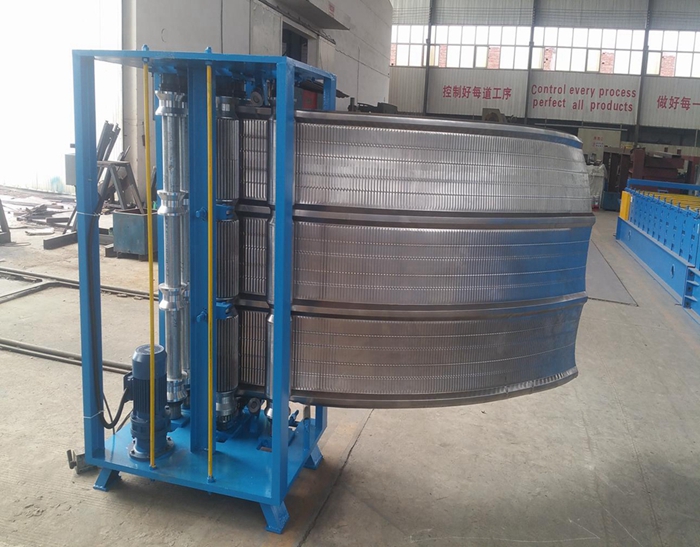

Roof sheet rolling machines are sophisticated tools designed to manufacture roof sheets from metal coils. These machines utilize a series of rollers to shape and form the metal into specific profiles suitable for roofing applications. Common materials processed include steel, aluminum, and other metal alloys, which are known for their durability and versatility in construction.

The operation of these machines is automated to a significant extent, allowing for high-speed production with precise measurements. A typical machine is equipped with features such as a decoiler, leveling system, forming stations, cutting mechanisms, and control systems. This intricate design ensures that manufacturers can produce high-quality roofing sheets that meet the varying requirements of the construction industry.

The Role of Factories in Production

Roof sheet rolling machine factories are integral to the construction sector, providing the necessary equipment that supports the large-scale production of roofing materials. These factories not only focus on manufacturing the machines themselves but often offer customized solutions based on the unique needs of their clients. The versatility of these machines allows for different profiles, allowing builders to choose designs that align with architectural aesthetics and functional requirements.

Moreover, factories play a crucial role in innovation and technology advancement. With the rapid pace of development in manufacturing technologies, many roof sheet rolling machine factories are investing heavily in research and development to enhance machine performance. These advancements may include improved energy efficiency, enhanced automation, and features that allow for greater flexibility in design production.

roof sheet rolling machine factory

Challenges and Solutions in the Industry

While the future appears bright for roof sheet rolling machine factories, the industry does not come without its challenges. Raw material costs can fluctuate significantly, impacting production costs. Additionally, the demand for sustainable and eco-friendly materials is rising, urging manufacturers to adapt and evolve. In response, leading factories are prioritizing the use of recyclable materials and incorporating energy-efficient technologies in their operations.

The global market also presents obstacles, as many factories must navigate diverse regulations and standards for construction materials in various countries. Staying compliant while maintaining cost-effectiveness requires ingenuity and meticulous planning. Consequently, successful factories have established strong relationships with suppliers and consistently invest in quality control processes to ensure their products meet the highest standards.

Market Trends and Future Prospects

The roof sheet market is on an upward trajectory, driven by rapid urbanization and infrastructure development across the globe. With an increasing number of residential and commercial buildings being constructed, the demand for quality roofing materials remains robust. Roof sheet rolling machine factories are poised to benefit significantly from this growth, provided they can keep pace with the industry's evolving needs.

Additionally, the trend towards automation within manufacturing processes is creating new opportunities. Factories that adopt smart technologies, such as IoT (Internet of Things) and AI (Artificial Intelligence), can enhance operational efficiency and product quality. These technologies will enable factories to monitor equipment performance in real-time, predict maintenance needs, and ultimately reduce downtime.

Conclusion

In conclusion, roof sheet rolling machine factories represent a vital segment of the construction industry's supply chain. They supply the necessary machinery to produce high-quality roofing products that are crucial for modern architecture. As the industry continues to evolve, these factories will need to embrace innovation and overcome challenges to meet the growing demand for sustainable and efficient roofing solutions. With the right strategies in place, roof sheet rolling machine factories will remain essential players in shaping the skylines of tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025