Suppliers and Manufacturers of Machines for Roof Sheet Production and Fabrication

The Importance of Roof Sheet Making Machines in the Construction Industry

In today's rapidly evolving construction industry, the need for durable and efficient building materials has never been more critical. One of the essential components of modern structures is the roof, which must not only provide protection but also contribute to the aesthetic appeal of a building. Roof sheet making machines have emerged as key players in the manufacturing of roofing materials, optimizing the production process and ensuring high-quality outputs. This article explores the significance of roof sheet making machines, their suppliers, and manufacturers, highlighting their impact on construction projects worldwide.

The Role of Roof Sheet Making Machines

Roof sheet making machines are specialized equipment designed to produce metal roofing sheets. These machines are capable of delivering a variety of profiles, such as corrugated, trapezoidal, and tile-like patterns, made from materials like galvanized steel and aluminum. The production process typically involves feeding raw metal coils into the machine, which then shapes and cuts them into the desired formats.

The efficiency of these machines has revolutionized the roofing sector. By automating the manufacturing process, roof sheet making machines significantly reduce labor costs and minimize waste. They offer precision engineering, which ensures that every sheet produced meets exact specifications. This level of accuracy is essential, as any discrepancies can lead to structural issues or aesthetic inconsistencies during installation.

Suppliers and Manufacturers in the Industry

The market for roof sheet making machines is vast, with numerous suppliers and manufacturers offering a range of products

. These companies play a vital role in the construction supply chain, providing high-quality machinery that meets the diverse needs of builders and contractors.When selecting a roof sheet making machine supplier, it's vital to consider several factors, such as machine specifications, production capacity, and after-sales support. Leading manufacturers often provide customized solutions, allowing clients to choose features that align with their specific requirements. For instance, some machines may offer additional capabilities such as integrated cutting and bending functions, enhancing production flexibility.

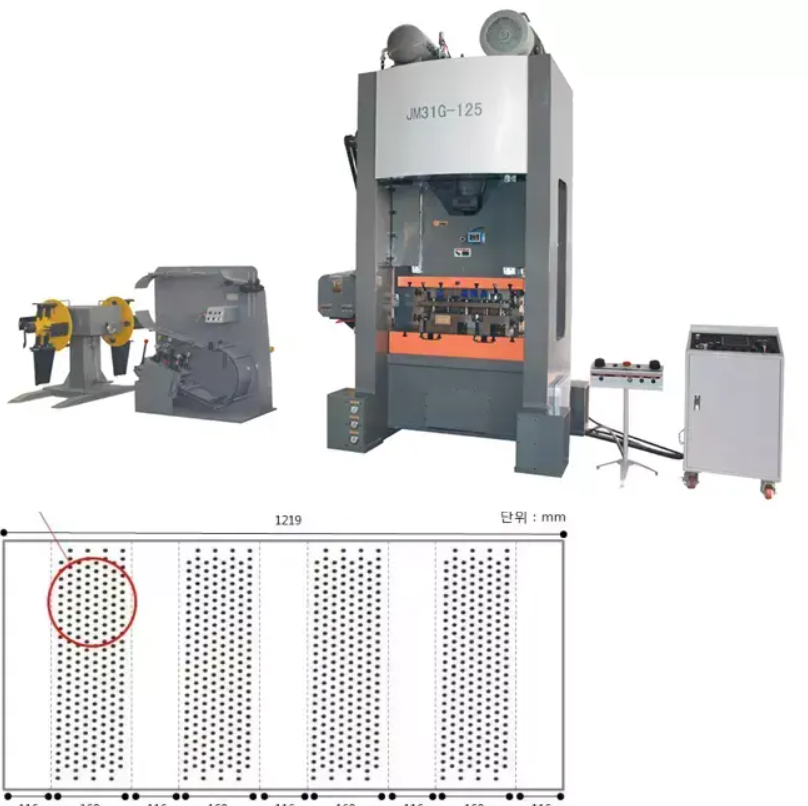

roof sheet making machine suppliers manufacturer

Moreover, many suppliers are focused on delivering technologically advanced machines that incorporate automation, reducing operational costs and increasing output. Features like programmable logic controllers (PLCs) and touch-screen interfaces enable operators to manage production processes effectively. Reliability and durability are also critical factors; quality machines can operate efficiently over extended periods, minimizing downtime for maintenance and repairs.

The Global Market and Future Trends

The global market for roof sheet making machines is experiencing steady growth, driven by rising construction activities and increased demand for sustainable building materials. In recent years, there has been a notable shift towards environmentally friendly solutions, with manufacturers exploring options such as recyclable materials in their products.

As the construction industry continues to innovate, advanced technologies such as Industry 4.0 and smart manufacturing are gaining traction. Roof sheet making machines are expected to integrate these trends, improving efficiency through data analytics and IoT capabilities. By utilizing smart technologies, manufacturers can monitor machine performance in real-time, further reducing waste and enhancing production capabilities.

Conclusion

Roof sheet making machines are indispensable tools for the modern construction industry. Their ability to streamline the production of quality roofing materials has made a significant impact on construction efficiency and project timelines. As suppliers and manufacturers continue to innovate and adapt to market demands, the potential for further advancements in this sector remains promising.

Investing in high-quality roof sheet making machines can offer substantial returns for construction businesses, paving the way for more sustainable and aesthetically pleasing buildings. As global infrastructure continues to expand and evolve, the role of these machines will only become more critical, solidifying their place in the future of construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025