Roof Sheet Production Equipment Manufacturers and Suppliers in the Industry

Roof Sheet Making Machine Suppliers and Factories

In the contemporary construction industry, the demand for high-quality roofing materials is growing exponentially. As a result, roof sheet making machines have become a crucial part of production lines for manufacturers globally. These machines are essential for producing metal roofing sheets, which are not only durable and long-lasting but also aesthetically appealing and environmentally friendly. This article delves into the significance of roof sheet making machine suppliers and factories, highlighting their roles, processes, and contributions to the construction sector.

Understanding Roof Sheet Making Machines

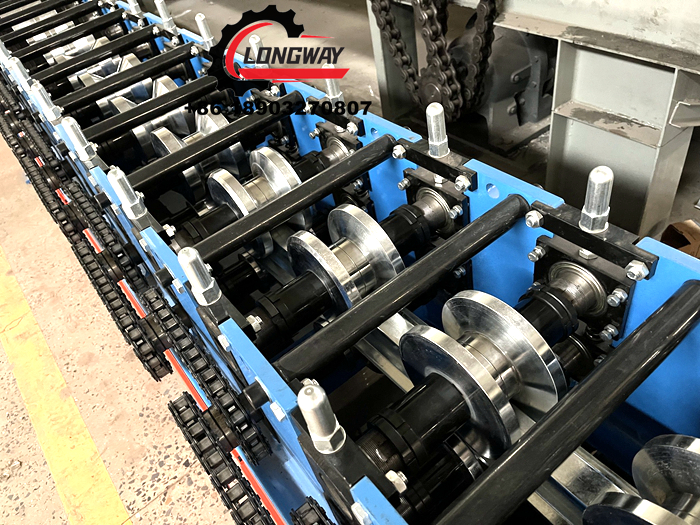

Roof sheet making machines are sophisticated pieces of equipment designed to produce a variety of roofing sheets, primarily made from metals such as steel, aluminum, and zinc. These machines operate through a series of processes that include decoiling, shearing, and profiling, transforming raw metal coils into finished roofing sheets. The resulting products can vary in size, shape, and design, catering to different architectural needs and preferences.

The Role of Suppliers

Suppliers of roof sheet making machines are instrumental in connecting manufacturers with the technology they require. They offer a variety of machines tailored to meet diverse production needs, including single-layer and double-layer roofing machines, roll-forming machines, and hydraulic shearing machines. Established suppliers not only provide equipment but also offer technical support, maintenance services, and spare parts, ensuring smooth operations for their clients.

One of the critical aspects that set reputable suppliers apart is their adherence to quality standards. Suppliers often partner with leading machine manufacturers to source equipment that meets international quality and safety standards. This commitment to quality ensures that manufacturers can produce reliable and durable roofing materials that comply with industry regulations.

The Importance of Factories

roof sheet making machine suppliers factories

The factories where roof sheet making machines are manufactured play a vital role in the overall quality of the equipment. These factories employ skilled engineers and technicians who specialize in designing and assembling machines that incorporate advanced technology and innovative features. Many of these factories are equipped with state-of-the-art facilities that utilize automated processes, ensuring high efficiency and precision in production.

Additionally, factories often conduct rigorous testing of the machines before they reach the market. This testing phase is crucial for identifying and rectifying any potential issues, ensuring that the machines delivered to suppliers and subsequently to manufacturers are of the highest quality.

Technological Advancements

With the rapid advancement of technology, roof sheet making machines are becoming increasingly sophisticated. Modern machines are equipped with computer numerical control (CNC) systems, allowing for greater precision and automation. This technology helps manufacturers produce roofing sheets with minimal error and at a faster rate, ultimately leading to higher productivity and reduced labor costs.

Moreover, innovations in energy efficiency and sustainability are gaining traction in the manufacturing of roof sheet making machines. Factories are now incorporating eco-friendly practices in their operations, thereby reducing the carbon footprint of the production process. This shift towards sustainability not only benefits the environment but also aligns with the growing demand for green building materials.

Conclusion

The collaboration between roof sheet making machine suppliers and factories is essential in meeting the rising demand for high-quality roofing materials in the construction industry. By providing advanced machinery and upholding rigorous quality standards, suppliers ensure that manufacturers can produce durable and reliable roofing sheets for various applications. As technological advancements continue to shape the industry, the importance of these suppliers and factories will only increase. In a world that prioritizes both quality and sustainability, the role of roof sheet making machines stands at the forefront of modern construction, paving the way for innovative and environmentally responsible building solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025