roof sheet making machine suppliers companies

Understanding Roof Sheet Making Machine Suppliers An Essential Player in the Construction Industry

In the modern construction landscape, roof sheets have become a crucial component due to their durability, aesthetic appeal, and cost-effectiveness. The demand for various types of roofing materials has surged, leading to the emergence of specialized machinery designed for producing roof sheets. Consequently, roof sheet making machine suppliers play a vital role in not just the supply chain, but also in ensuring that construction projects are completed on time and within budget.

The Importance of Roof Sheet Making Machines

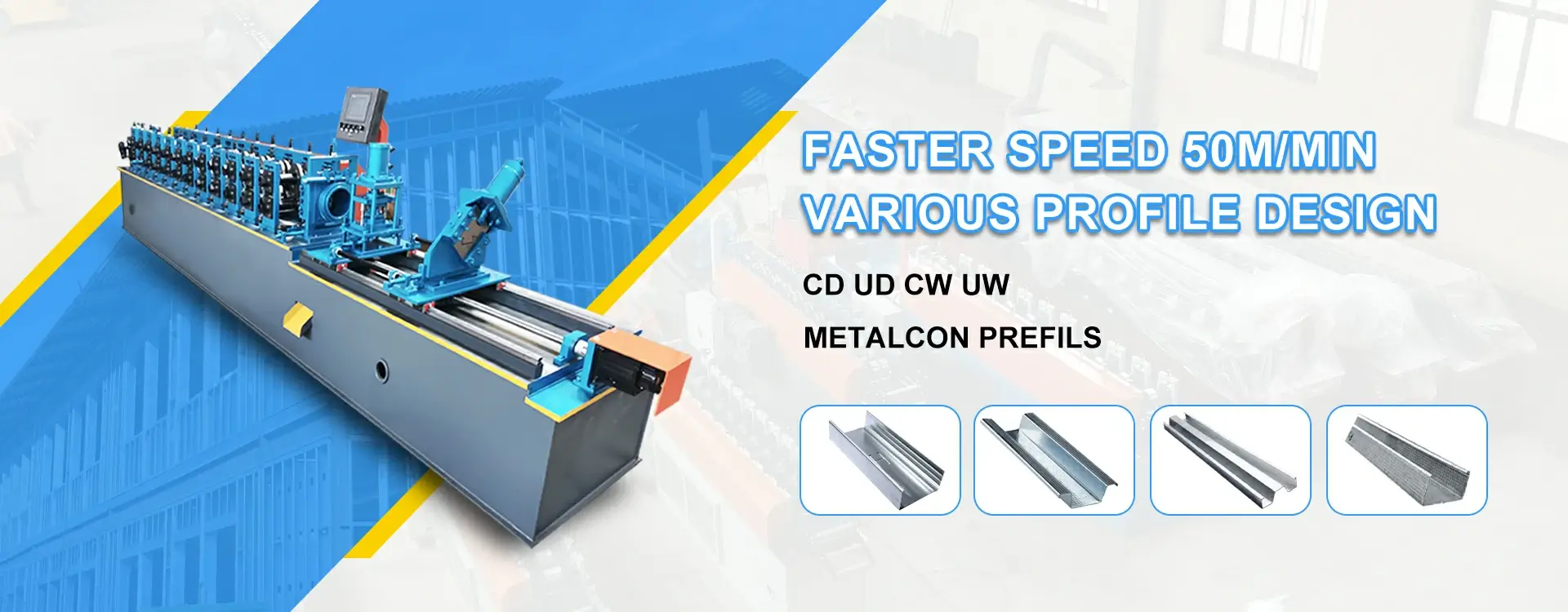

Roof sheets are utilized in a wide array of applications, including residential homes, commercial buildings, industrial facilities, and agricultural structures. These sheets are available in various materials such as metal, plastic, and composites, each offering unique benefits. The process of manufacturing roof sheets involves various stages including roll forming, cutting, and sometimes applying protective coatings. This complexity necessitates the use of advanced machinery that can ensure precision, high productivity, and consistent quality.

Roof sheet making machines are designed for mass production, which enables manufacturers to meet the growing demand while maintaining quality. Suppliers of these machines provide several features that enhance their usability, such as automation, energy efficiency, and flexibility in production. As such, choosing the right supplier can significantly impact a company's bottom line and operational efficiency.

Key Features to Consider in Suppliers

When looking for roof sheet making machine suppliers, several essential factors need to be considered

1. Quality of Machinery The reliability and durability of the machines are paramount. Suppliers who offer high-quality products not only ensure operational efficiency but also reduce maintenance costs and downtime.

2. Customization Options Different projects may require unique specifications. Suppliers that allow customization—be it in size, shape, or material type—offer significant advantages for manufacturers targeting niche markets.

roof sheet making machine suppliers companies

3. Technical Support and Service A reputable supplier should provide excellent technical support, including installation and training services. Ongoing support can also be crucial for troubleshooting and maintaining efficiency.

4. Warranty and After-Sales Service Quality suppliers typically offer warranties that cover parts and service, ensuring peace of mind for buyers. Good after-sales support can also enhance the longevity of the machines.

5. Cost-Effectiveness While it can be tempting to opt for the cheapest machine available, it’s essential to consider the total cost of ownership, including energy consumption, maintenance needs, and lifespan.

The Role of Technology in Roof Sheet Manufacturing

Advancements in technology have had a profound impact on the roof sheet manufacturing industry. Automation has emerged as a critical trend, enabling manufacturers to increase production speeds and reduce labor costs. Additionally, innovative materials and coatings allow for enhanced product durability and energy efficiency, making roof sheets more appealing to environmentally conscious consumers.

Suppliers who stay abreast of technological advancements are better positioned to offer state-of-the-art machinery that can accommodate evolving production needs. Investing in modern equipment can help manufacturers differentiate themselves in a competitive market, providing products that meet or exceed customer expectations.

Conclusion

The significance of selecting the right roof sheet making machine supplier cannot be overstated. A strong partnership with reputable suppliers can help manufacturers fulfill the rising demand for high-quality roofing materials while ensuring operational efficiency. As construction projects become more sophisticated and demanding, the role of these suppliers will continue to grow, shaping the future landscape of the construction industry.

Ultimately, potential buyers should conduct thorough research and compare different suppliers based on their offerings, reliability, and support services. Doing so will ensure they make informed decisions that align with their production goals and the demands of the market. As the industry evolves, staying connected with innovative suppliers will be key to achieving sustainable growth and success in the roofing sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025