roof sheet machine for sale company

Finding the Right Roof Sheet Machine for Sale A Comprehensive Guide

When it comes to the construction and manufacturing industry, the demand for high-quality roofing materials has always been on the rise. Roof sheet machines have become essential for businesses looking to produce durable and reliable roofing sheets efficiently. If you're in the market for a roof sheet machine for sale, it's crucial to understand the factors that determine the right choice for your needs.

Understanding Roof Sheet Machines

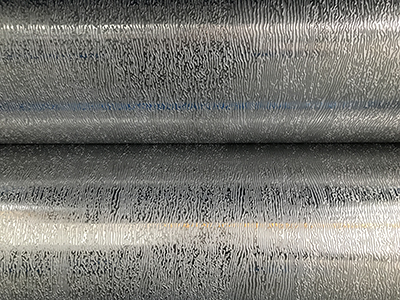

Roof sheet machines are advanced industrial devices designed to manufacture metal roofing sheets from raw materials such as steel or aluminum. These machines can create various types of roofing sheets, including corrugated, wave, and standing seam profiles. The production process involves several stages, including feeding the metal coils, forming them into desired shapes, and cutting them to specific lengths.

Key Features to Consider

When searching for a roof sheet machine for sale, there are several critical features to consider

1. Production Capacity Assess your production requirements to find a machine that meets your output needs. Machines come in different sizes and capabilities, so consider the volume of sheets you need to produce daily or weekly.

2. Material Compatibility Ensure that the machine you choose can work with the types of materials you plan to use. Some machines are designed specifically for certain metals, while others offer versatility to accommodate a range of materials.

3. Automation Level The level of automation can significantly impact efficiency and labor costs. Fully automated machines can operate with minimal manual intervention, while semi-automated options may require more hands-on work. Evaluate your workforce and decide which level of automation best suits your business model.

4. Quality of Output The finished product's quality is paramount. Look for machines that consistently produce high-quality sheets with precise dimensions and excellent surface finishes. Reading customer reviews and seeking samples can help assess a machine's performance.

roof sheet machine for sale company

5. Ease of Operation and Maintenance A user-friendly machine will reduce training time for your staff. Furthermore, consider the maintenance requirements. Machines that are easier to maintain will save you time and costs in the long run.

6. After-Sales Support Reliable after-sales service is essential when investing in industrial machinery. Check if the manufacturer provides warranty options, spare parts availability, and technical support. This ensures that your operations will not be disrupted by equipment failures.

Evaluating Manufacturers

Not all manufacturers are created equal, and the reputation of the company you choose to buy from can greatly influence your satisfaction with the purchase. Research various companies and consider the following

- Experience Look for manufacturers with a proven track record in producing roof sheet machines. Experience often correlates with innovation and quality control in their production processes.

- Customer Feedback Check online reviews and testimonials from other customers. Positive feedback can indicate that a company's machines are reliable and their customer service is responsive.

- Certifications Manufacturers that adhere to international standards (such as ISO certifications) often provide higher-quality machines. These certifications demonstrate a commitment to quality and safety.

Conclusion

Acquiring a roof sheet machine for sale is a significant investment for any business in the construction sector. By considering factors such as production capacity, material compatibility, level of automation, and after-sales support, you can make a well-informed decision. Take the time to research various manufacturers and gather feedback from existing customers to ensure that you choose a machine that enhances your production capabilities and meets your business needs.

As demand for roofing materials continues to grow, investing in a reliable roof sheet machine can position your company for success in the competitive market. By enhancing your manufacturing processes, you’ll not only meet customer needs but also remain at the forefront of your industry, driving both growth and innovation.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025