roof sheet machine for sale companies

Roof Sheet Machine for Sale A Comprehensive Guide

In the construction and manufacturing sector, the demand for high-quality roofing materials has increased significantly over the years. With the ongoing advancements in technology and manufacturing processes, one of the most sought-after machines in this industry is the roof sheet machine. This article aims to provide insights into the various aspects of roof sheet machines for sale, including their functionalities, types, benefits, and factors to consider when purchasing one.

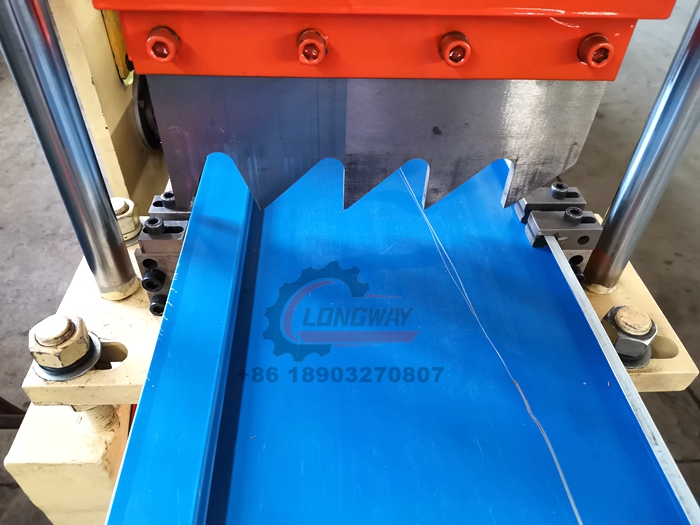

Understanding Roof Sheet Machines

Roof sheet machines, also known as roofing sheet roll forming machines, are specialized equipment used to manufacture roofing sheets from metal coils. These machines are designed to produce sheets of various profiles and patterns, catering to different architectural and structural needs. The primary materials used in these machines typically include galvanized steel, aluminum, and color-coated sheets.

Types of Roof Sheet Machines

There are several types of roof sheet machines available in the market, each serving specific purposes. The most common types include

1. Double Layer Roof Sheet Machine This machine allows the production of two different profiles in a single run, offering versatility and efficiency for manufacturers.

2. Single Layer Roof Sheet Machine Ideal for those focusing on a single roof profile, this machine is simpler but highly effective for producing consistent quality sheets.

3. Ibr Roof Sheet Machine Designed specifically for producing IBR (Inverted Box Rib) sheets, this machine is popular in the southern regions where this profile is preferred.

4. Corrugated Roof Sheet Machine This machine specializes in creating corrugated sheets that are widely used in residential, commercial, and industrial applications.

5. Color Coated Roof Sheet Machine This variant not only shapes the sheets but also applies a color coat, providing aesthetic appeal and additional protection against rust.

Benefits of Roof Sheet Machines

Investing in a roof sheet machine comes with numerous benefits, which are essential for manufacturers looking to enhance their production capabilities

.- Efficiency Roof sheet machines are designed for high-speed production, allowing users to meet large orders and tight deadlines with ease.

roof sheet machine for sale companies

- Cost-Effective By investing in a roof sheet machine, manufacturers can save on labor costs and minimize material waste. Furthermore, producing sheets in-house allows for better control over the quality and type of materials used.

- Customization Many roof sheet machines provide options for custom configurations, enabling manufacturers to produce sheets according to specific customer requirements in terms of size, profile, and color.

- Durability Machines are built to withstand heavy workloads and consistent use, ensuring longevity and reliability in production.

Factors to Consider When Purchasing a Roof Sheet Machine

When considering the purchase of a roof sheet machine, several factors should be evaluated to ensure the best investment

1. Production Capacity Assess how much output you need and choose a machine that can meet your production demands.

2. Material Compatibility Ensure the machine can handle the types of materials you plan to use, such as stainless steel or aluminum.

3. Flexibility If you anticipate needing different profiles in the future, consider a double-layer machine for versatility.

4. Technology and Automation Modern machines come with advanced technology, including PLC controls and touch screen operation, which can enhance efficiency and reduce the likelihood of errors.

5. Warranty and Support A reliable warranty and good customer service from the manufacturer can save you from future headaches in case of machine issues.

6. Cost Finally, weigh the cost against the benefits to ensure you are making a sound investment. Compare prices from various suppliers and consider the long-term savings a machine can provide.

Conclusion

Roof sheet machines play a crucial role in the construction industry by providing high-quality roofing materials efficiently and cost-effectively. With the variety of machines available, manufacturers can choose the right equipment to meet their specific needs. By considering the aforementioned factors critically, you can make a confident decision when purchasing a roof sheet machine for sale, ultimately contributing to the growth and success of your business in the competitive roofing market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025