roof roll forming machine in china

The Evolution and Importance of Roof Roll Forming Machines in China

In recent years, the construction industry has witnessed significant advancements, particularly in the production of roofing materials. Among these innovations is the roof roll forming machine, a vital piece of equipment that has transformed the process of creating roofing sheets. In China, where the demand for efficient and durable building materials is on the rise, these machines have become increasingly important.

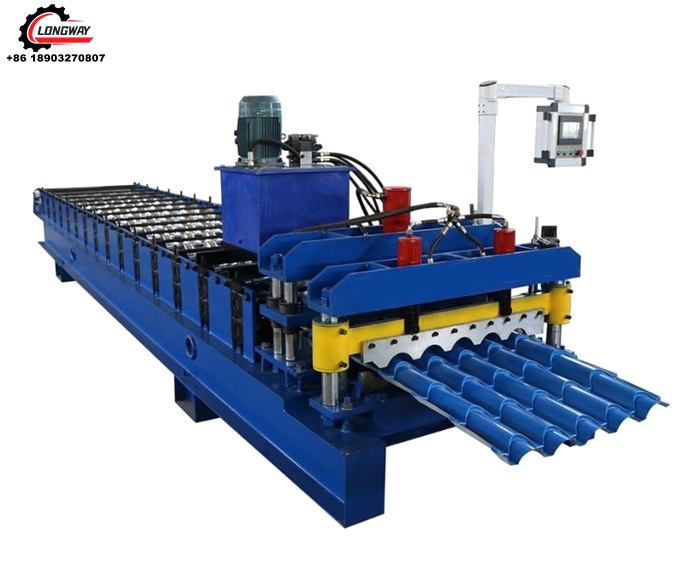

Understanding Roof Roll Forming Machines

Roof roll forming machines are automated devices that shape metal sheets into specific profiles used in roofing applications. These machines work by feeding a flat metal coil through a series of rollers, which gradually bends and forms the material into the desired shape. The resulting panels can be used for various types of roofs, offering durability, weather resistance, and aesthetic appeal.

The versatility of roof roll forming machines allows manufacturers to create different profiles, such as standing seam, corrugated, and tile-like designs. This flexibility caters to a wide range of architectural styles and offers builders and homeowners various options to choose from. Moreover, the precision and consistency provided by these machines ensure that each panel meets strict quality standards.

The Chinese Market for Roof Roll Forming Machines

China is one of the largest producers of roll forming machines globally, including roof roll forming machines. The country has established a robust manufacturing infrastructure that focuses not only on the production of these machines but also on innovation and design improvements. Crucial companies in this sector are continually developing new technologies, resulting in faster production rates, enhanced energy efficiency, and smarter automation features.

The domestic demand for roofing materials in China is driven by rapid urbanization and infrastructure development. With a growing population and increased investment in construction, the need for high-quality roofing solutions has never been greater. As a result, the market for roof roll forming machines has expanded significantly, with both local and international manufacturers seeking to capitalize on this opportunity.

roof roll forming machine in china

Advantages of Using Roof Roll Forming Machines

One of the main advantages of roof roll forming machines is their efficiency. Traditional methods of manufacturing roofing materials can be time-consuming and labor-intensive. In contrast, these machines can produce large quantities of materials in a short time, significantly reducing labor costs and production time. This efficiency is crucial in meeting the demands of large construction projects, where time is often of the essence.

Additionally, roof roll forming machines produce less waste compared to conventional methods. Given that the metal is shaped from a continuous coil, the amount of scrap material generated is minimized. This aspect is particularly important in today’s environmentally conscious market, where sustainability plays a pivotal role in the manufacturing process.

Quality and Durability

Another key benefit of roof roll forming machines is the quality of the products they produce. The precision engineering involved ensures that each panel is uniform and fits together seamlessly during installation. This accuracy not only enhances the aesthetic appeal of the roof but also contributes to its structural integrity.

Moreover, the materials used in conjunction with roll forming machines, typically high-strength steel or aluminum, offer remarkable durability. These roofing solutions are designed to withstand harsh weather conditions, including heavy rains, snow, and strong winds. This resilience is a critical factor in the growing preference for roll-formed roofing products in both residential and commercial sectors.

Conclusion

In summary, roof roll forming machines represent a significant advancement in the manufacturing of roofing materials, particularly in China. With their efficiency, quality, and environmental benefits, these machines play an essential role in meeting the increasing demands of the construction industry. As the market continues to grow and evolve, the importance of roof roll forming machines in creating durable, high-quality roofing solutions will only become more pronounced. The future of roofing in China looks promising, driven by innovation and a commitment to excellence in manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025