roof panel roll forming machine manufacturer

The Importance of Roof Panel Roll Forming Machines in Modern Construction

In today's fast-paced construction industry, efficiency and precision are paramount. Among the numerous technologies that contribute to streamlined processes, roof panel roll forming machines stand out as invaluable assets. These machines are vital for producing high-quality roofing panels quickly and accurately, making them essential for manufacturers and builders alike.

Understanding Roof Panel Roll Forming Machines

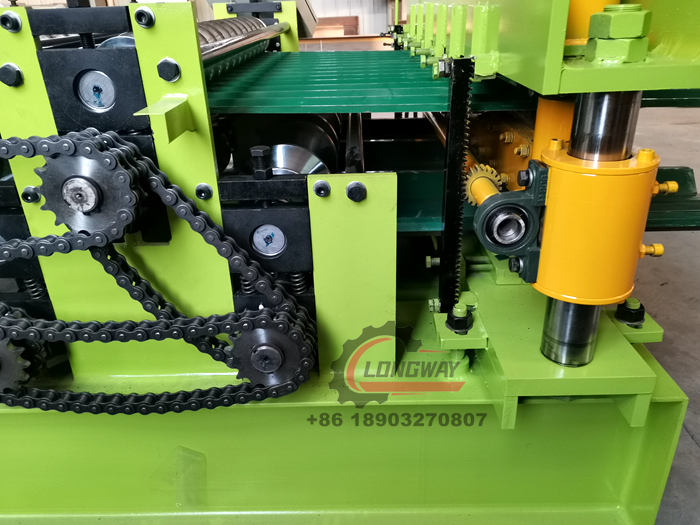

Roof panel roll forming machines are specialized equipment used to transform flat sheets of metal into roofing panels of various profiles. This process involves feeding metal coils into the machine, which then gradually shapes the material through a series of rollers. Each roller progressively bends the metal until it achieves the desired form. The result is a uniform, durable roofing panel ready for installation.

The versatility of these machines allows manufacturers to produce panels in different sizes, thicknesses, and styles, such as standing seam, corrugated, or flat panels. This adaptability ensures that builders can obtain the specific roofing solutions they need for various projects, from residential homes to commercial warehouses.

Key Features of Roof Panel Roll Forming Machines

1. Precision Engineering One of the standout features of roof panel roll forming machines is their ability to produce highly accurate and consistent panels. The use of computer numerical control (CNC) technology ensures that each panel is manufactured to exact specifications, reducing waste and the need for rework.

2. Speed and Efficiency Modern roll forming machines operate at impressive speeds, producing thousands of linear feet of roofing panels in a single day. This efficiency not only accelerates the construction process but also allows manufacturers to meet tight deadlines without compromising quality.

3. Durability Roof panel roll forming machines are built to last, often constructed from high-quality materials that withstand the rigors of continuous operation. This durability ensures that they provide consistent performance over time, making them a wise investment for manufacturers.

4. Ease of Operation Most roll forming machines are designed with user-friendly interfaces and automation features that simplify operation. This allows operators to change settings quickly for different panel designs, optimizing production without extensive training.

roof panel roll forming machine manufacturer

Benefits for Manufacturers and Builders

The use of roof panel roll forming machines brings numerous benefits to both manufacturers and builders. For manufacturers, the ability to produce customized panels on-demand enhances their competitiveness in the market. They can cater to specific client requirements and quickly adjust to changing market trends, all while maintaining cost-efficiency.

Builders, on the other hand, benefit from the high-quality materials produced by these machines. The precise dimensions and robust nature of roll-formed panels ensure that they fit correctly and offer excellent performance under various weather conditions. Moreover, the lightweight nature of many roll-formed panels reduces the overall load on structures, contributing to better energy efficiency and easier transport.

Environmental Considerations

Sustainability is an increasingly important factor in today's construction landscape. Roof panel roll forming machines contribute to environmentally friendly practices by minimizing waste. The process efficiently utilizes raw materials, and many manufacturers are using recycled metal coils in their production. This not only conserves natural resources but also reduces the carbon footprint associated with manufacturing new metal products.

Choosing the Right Manufacturer

Selecting the right roof panel roll forming machine manufacturer is crucial for businesses looking to invest in this technology. Key factors to consider include the manufacturer’s experience, the quality of the machines, customer support, and after-sales services. Companies should seek manufacturers that offer custom solutions, as specific project needs can vary greatly depending on the application.

Conclusion

Roof panel roll forming machines revolutionize the way roofing materials are produced, enhancing efficiency, accuracy, and sustainability in construction. As the industry continues to evolve, investing in state-of-the-art roll forming technology will be essential for manufacturers and builders aiming to stay ahead of the competition. With their ability to deliver high-quality, customized roofing solutions quickly, these machines not only streamline production but also contribute to the overall success of construction projects.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025