Roof Panel Roll Forming Machine Manufacturers Offering Quality Machines for Sale

Roof Panel Roll Forming Machine for Sale A Comprehensive Overview

In the world of construction and manufacturing, efficiency and precision are paramount. The demand for high-quality roofing materials has led to the proliferation of advanced machinery that streamlines production processes. Among these machines, the roof panel roll forming machine stands out as an essential tool for manufacturers, contractors, and builders alike. This article aims to provide an in-depth look at roof panel roll forming machines for sale, focusing on their features, benefits, and why investing in one can significantly enhance your roofing operations.

What is a Roof Panel Roll Forming Machine?

A roof panel roll forming machine is a specialized piece of equipment designed to create metal roofing panels. It operates by feeding a coil of metal, typically galvanized steel or aluminum, through a series of rollers. These rollers systematically shape the metal into desired profiles, producing panels that are consistent in thickness and shape. The machine can produce various roof panel designs, including standing seam, corrugated, and flat panels, accommodating diverse architectural needs.

Key Features of Roof Panel Roll Forming Machines

1. High Production Efficiency Modern roll forming machines are designed for high-speed production, allowing manufacturers to produce large quantities of roofing panels in a fraction of the time it would take using traditional methods.

2. Precision Engineering Advanced technology enables these machines to achieve precise measurements and consistent quality across all panels produced. This is crucial for ensuring proper installation and longevity of roofing systems.

3. Versatile Design Options Many machines come with interchangeable tooling, allowing users to quickly switch between different panel profiles. This versatility is beneficial for companies looking to accommodate a wide range of projects.

4. User-Friendly Controls Most roof panel roll forming machines are equipped with intuitive control systems that simplify operation. Operators can easily adjust settings and monitor production, reducing the likelihood of errors and enhancing overall productivity.

5. Durable Construction These machines are typically built from robust materials to withstand the rigors of continuous operation. Durable components ensure a long lifespan and reduced maintenance costs.

Benefits of Investing in a Roof Panel Roll Forming Machine

1. Cost Savings While the initial investment in a roll forming machine may seem significant, the long-term savings are undeniable. By producing panels in-house, businesses can significantly reduce material costs and eliminate third-party supplier expenses.

roof panel roll forming machine for sale manufacturers

2. Customization Having the ability to manufacture your own roofing panels allows for greater customization. Whether it’s specific dimensions, colors, or profiles, manufacturers can meet client specifications more effectively.

3. Quality Control Controlling the production process means that manufacturers can maintain high standards of quality and consistency. This not only boosts customer satisfaction but also reduces the likelihood of defects and returns.

4. Faster Project Turnaround With the capability to produce panels on-demand, project timelines can be significantly shortened. This is especially beneficial in fast-paced construction environments where time is of the essence.

5. Sustainability In-house production minimizes waste and allows for the recycling of scrap material, contributing to more sustainable practices in construction and manufacturing.

Choosing the Right Roof Panel Roll Forming Machine

When considering the purchase of a roof panel roll forming machine, several factors come into play

- Production Capacity Assess your production needs to determine the appropriate speed and capacity requirements for the machine.

- Panel Types Identify the types of panels you wish to produce and ensure the machine can accommodate these designs.

- Manufacturer Reputation Purchase from established manufacturers who offer reliable machines, excellent customer service, and support for maintenance and parts.

- Budget Considerations While it's vital to invest in a quality machine, staying within your budget is equally important. Compare features and prices across different brands.

Conclusion

Investing in a roof panel roll forming machine is a strategic decision that can transform your roofing operations. With the ability to produce high-quality, customizable panels efficiently, these machines offer numerous advantages over traditional production methods. As the demand for innovative roofing solutions continues to grow, having the right machinery will position your business for success in a competitive market. Make an informed decision, and take the first step toward elevating your production capabilities.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

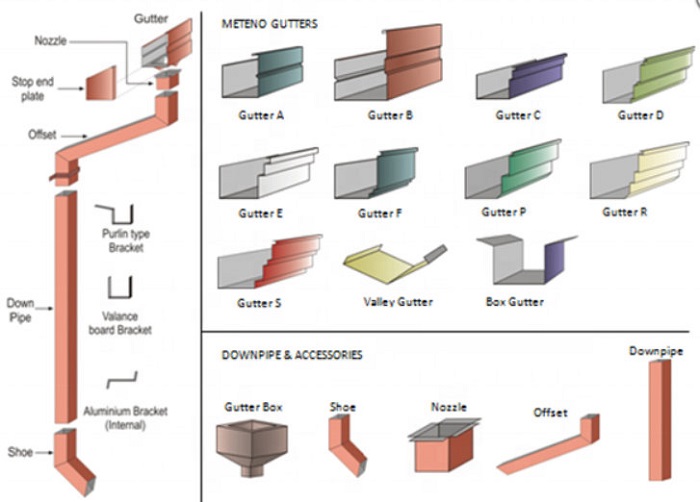

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025