Roof Panel Roll Forming Machine Manufacturing Facility Overview and Innovations

The Rise of Roof Panel Roll Forming Machine Factories

In the landscape of modern construction, efficiency and precision are paramount. As the demand for durable and lightweight materials increases, the significance of roof panel roll forming machine factories becomes ever more prominent. These factories specialize in producing high-quality metal roofing panels through advanced roll forming technology, which has revolutionized the construction industry.

Understanding Roll Forming Technology

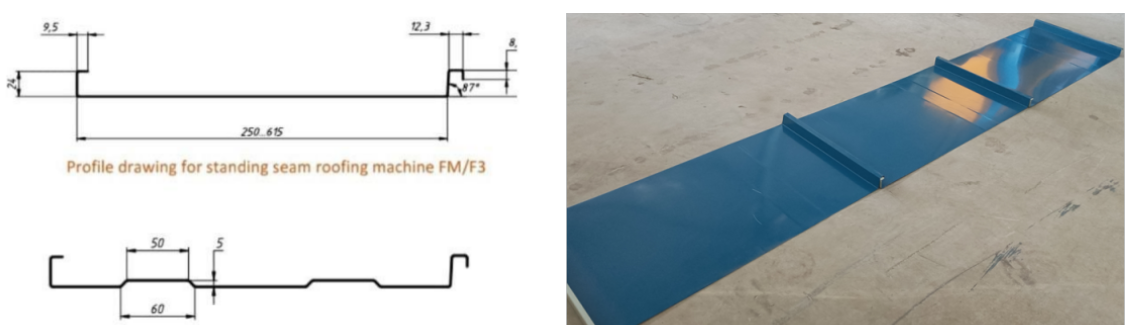

At the heart of a roof panel roll forming machine factory is the roll forming process itself. This technology involves the continuous bending of sheet metal through a series of rollers to create desired cross-sectional profiles. The process begins with flat metal sheets, usually made of galvanized steel or aluminum, which are fed into the machine. As the material passes through multiple rollers, it gradually acquires its final shape. This method is not only efficient but also ensures consistency and precision in the production of roofing panels.

The Advantages of Roll Forming

The benefits of using roll forming machines in manufacturing roof panels are manifold

. First and foremost, the process allows for the creation of complex shapes and designs that can enhance the aesthetic appeal of a building. With customizable options available, architects and builders can specify the dimensions and profiles that best meet their project’s requirements.Moreover, roll forming is known for its high production speed and minimal waste. The continuous operation of roll forming machines increases output, making it an economical choice for large-scale projects. Additionally, since the sheets are processed without cutting, the amount of scrap material is significantly reduced, leading to cost savings and environmental benefits.

The Role of Factories in the Supply Chain

roof panel roll forming machine factory

Roof panel roll forming machine factories play a critical role in the supply chain of the construction industry. These facilities not only produce roofing materials but also support other sectors such as HVAC, automotive, and even agricultural industries, where metal panels are essential. By ensuring a steady supply of high-quality roofing products, these factories help builders and contractors meet deadlines and stay within budget.

Furthermore, the rise of global construction demands has led to innovations within these factories. Many are now integrating smart technology, such as automation and IoT (Internet of Things), to enhance their production capabilities. Automated systems streamline operations, reduce labor costs, and improve product quality. This technological integration allows factories to respond swiftly to market changes and customer needs, ensuring they remain competitive.

Environmental Considerations

In recent years, there has been a growing emphasis on sustainability within the construction industry. Roof panel roll forming machine factories are increasingly adopting eco-friendly practices to align with these trends. By using recyclable materials and optimizing energy consumption, these facilities are helping to mitigate the environmental impact of construction activities. Additionally, metal roofing panels manufactured through roll forming boast longevity and energy efficiency, further contributing to sustainable building practices.

Conclusion

As we look toward the future, the importance of roof panel roll forming machine factories cannot be overstated. These factories not only drive innovation and efficiency in the production of roofing materials, but they also support the broader goals of sustainability in the construction industry. With the continued evolution of technology and growing environmental awareness, the role of these factories will only expand, solidifying their place as essential players in modern construction.

As builders and architects continue to seek high-quality, durable, and aesthetically pleasing roofing solutions, the roof panel roll forming machine industry is poised for continued growth. This evolution will likely bring forth even more advancements, powering the future of construction one roof panel at a time.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025