roof panel roll forming machine company

The Evolution and Importance of Roof Panel Roll Forming Machines

In the world of construction and building materials, the demand for durable, efficient, and aesthetically pleasing roofing solutions has never been higher. One of the pivotal innovations in this sector is the roof panel roll forming machine. This sophisticated piece of equipment has transformed how roofing materials are produced and has become essential for manufacturers aiming to stay competitive in the market.

Understanding Roof Panel Roll Forming Machines

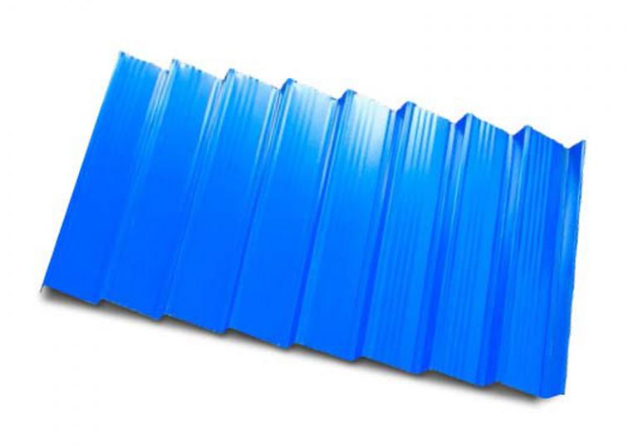

A roof panel roll forming machine is a specialized device designed to produce metal roofing panels from continuous coils of sheet metal. This process involves feeding a flat coil of material through a series of rollers that progressively shape it into the desired panel profile. The end result is a lightweight, strong, and weather-resistant roofing panel that can be used in various architectural applications.

The primary advantage of roll forming over traditional methods is efficiency. The machine can produce long lengths of roofing panels continuously, minimizing waste and optimizing production time. This is particularly valuable in large-scale construction projects where time and cost are critical factors.

Key Features and Technologies

Modern roof panel roll forming machines come equipped with advanced technologies to enhance their performance and versatility. Some key features include

1. Adjustable Roll Sets Many machines allow for quick changeovers to accommodate different panel profiles. This flexibility enables manufacturers to respond swiftly to market demands or customize products for specific projects.

2. Computerized Control Systems The integration of digital technology allows for precise control over the forming process. These systems can include touch-screen interfaces that monitor speed, temperature, and dimensions, ensuring consistent quality across batches.

3. High-Quality Materials and Design Top-tier roll forming machines are constructed from robust materials that can withstand the stresses of continuous operation. Additionally, the design usually incorporates safety features to protect operators and maintain machinery integrity.

4. Energy Efficiency With an increasing focus on sustainability, many manufacturers are developing machines that consume less energy without compromising output quality. Energy-efficient models can significantly reduce operational costs.

5. Automatic Cutting and Stacking Advanced machines integrate automatic cutting and stacking systems, allowing finished panels to be neatly arranged for packaging and shipping, further streamlining the production process.

roof panel roll forming machine company

Application and Market Demand

The versatility of roof panel roll forming machines means they can be used across various sectors, including residential, commercial, and industrial construction. Roof panels produced by these machines are commonly made from materials such as steel, aluminum, and stainless steel, all of which can be engineered to provide enhanced strength and corrosion resistance.

In recent years, the rise in construction activities worldwide, paired with a growing emphasis on energy-efficient and eco-friendly building practices, has driven demand for roll-formed roofing materials. Roof panels are not only valued for their practical benefits but also for their visual appeal. Designers and architects often opt for these materials to create sleek and modern aesthetic looks on buildings.

Choosing the Right Manufacturer

For businesses looking to invest in a roof panel roll forming machine, selecting the right manufacturer is crucial. Factors to consider include

- Reputation and Experience Choose a company with a solid track record in producing reliable machinery and who understands the unique demands of the roofing industry.

- Customization Options A good manufacturer should be able to offer customization based on specific production needs, allowing for a more tailored approach to your manufacturing processes.

- After-Sales Support Robust after-sales support, including installation, training, and maintenance services, can significantly enhance the longevity and efficiency of the equipment.

- Innovative Technology Investing in a manufacturer that continually updates their technology ensures access to the latest features, improving production capabilities.

Conclusion

The roof panel roll forming machine has radically changed the way roofing materials are manufactured. Its efficiency, versatility, and ability to produce high-quality roofing solutions make it an invaluable asset for construction companies today. As the industry continues to evolve, staying informed about advancements in roll forming technology is essential for any business looking to thrive in the competitive building materials market. With the right equipment and expertise, companies can meet the growing demands for robust, stylish roofing solutions that stand the test of time.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025