roofing tile roll forming machine company

The Evolution of Roofing Tile Roll Forming Machines A Comprehensive Look

In the modern construction industry, the demand for durable and aesthetically pleasing roofing materials has significantly increased. One of the most innovative advancements within this realm is the roofing tile roll forming machine. This machinery has revolutionized the production of roofing tiles, making the process more efficient, cost-effective, and environmentally friendly. In this article, we will explore what roofing tile roll forming machines are, their benefits, and the companies that lead the market in this technology.

Understanding Roofing Tile Roll Forming Machines

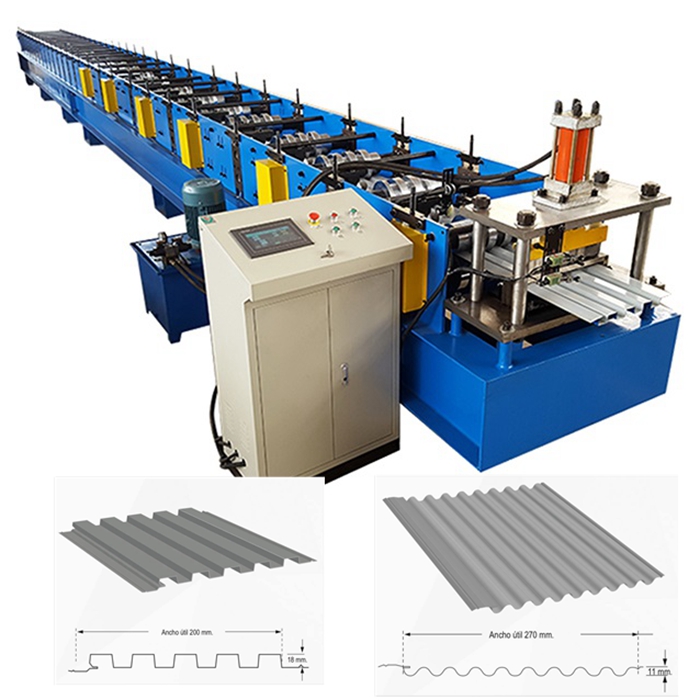

Roofing tile roll forming machines are specialized equipment used to produce metal roofing tiles in a continuous process. These machines transform flat metal sheets into beautifully shaped tiles through a series of precise rolls and dies. The process starts with feeding the flat steel into the machine, which then shapes it into the desired profile while ensuring uniformity and quality. The end result is a sturdy, lightweight, and attractive roofing material that can withstand harsh weather conditions.

Advantages of Roll Forming Machines

1. Efficiency and Speed One of the most significant advantages of using roofing tile roll forming machines is their efficiency. These machines can produce tiles rapidly, significantly reducing production time compared to traditional methods. This speed not only meets rising demands but also leads to cost savings for manufacturers.

2. Customization Modern roll forming machines offer versatility in customization. Manufacturers can modify the machine settings to produce different tile designs, profiles, and sizes according to client specifications. This ability to adapt to varying demands makes roll forming machines an invaluable asset in the roofing industry.

3. Consistency in Quality This machinery provides remarkable consistency in the quality of the finished products. The automated processes reduce human error, leading to uniform dimensions, thickness, and finishes in each tile. Such reliability is critical for ensuring the long-term performance of roofing systems.

roofing tile roll forming machine company

4. Sustainability As more people become environmentally conscious, the roofing industry is shifting towards sustainable practices. Roofing tile roll forming machines can utilize recyclable materials, reducing waste and energy consumption. Additionally, metal roofing often lasts longer than traditional materials, leading to fewer replacements and less environmental impact over time.

Leading Companies in the Market

Several companies have established themselves as leaders in the manufacturing of roofing tile roll forming machines. Among these, Xiamen Jinding Machinery Co., Ltd. stands out for its innovative design and production capabilities. They provide a range of models tailored to different business scales and roofing tile styles.

Another prominent player is Zhongyuan Machinery, known for its commitment to producing high-quality machinery that integrates the latest technologies. Their machines are equipped with advanced control systems that enhance precision and operational efficiency.

Wuxi Hengteng Roll Forming Machine Co., Ltd. focuses on delivering robust and durable roll forming solutions. Their commitment to customer service and comprehensive machine customization has earned them a loyal customer base.

Conclusion

The advancements in roofing tile roll forming machines have changed the landscape of roofing material production, offering faster, more-efficient, and environmentally friendly solutions. As construction evolves to meet contemporary demands, these machines will undoubtedly play a crucial role in shaping the future of roofing. The ongoing innovation from leading companies in this sector further emphasizes the importance of quality and adaptability in meeting diverse client needs. With the continued evolution of technology, the roofing industry is poised for exciting developments in the years to come, paving the way for enhanced building practices and sustainable construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025