Feb . 06, 2025 01:44

Back to list

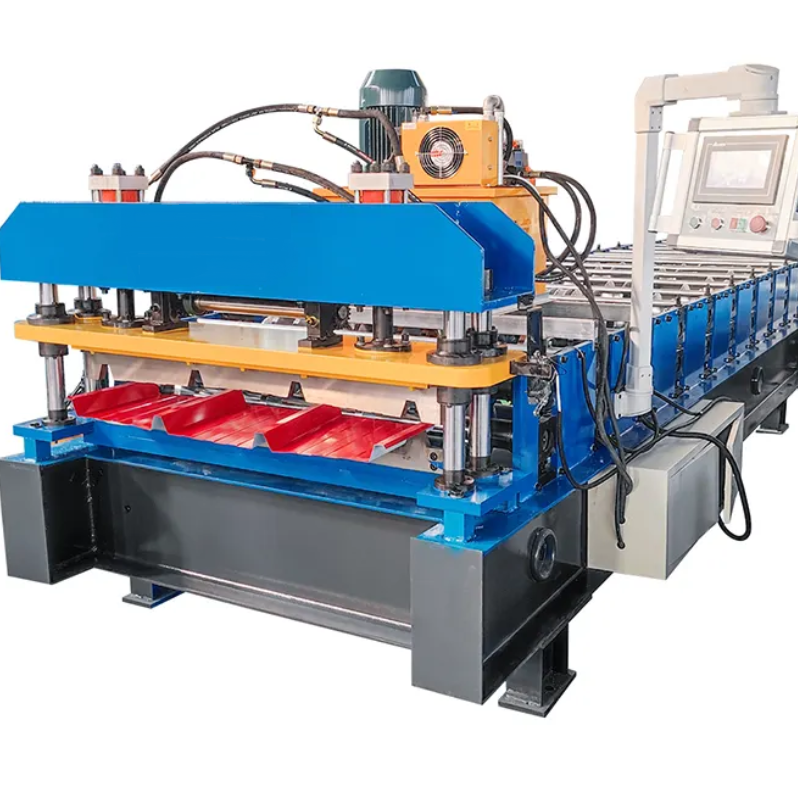

roofing tile roll forming machine

Selecting the right roofing tile roll forming machine is crucial for any business in the construction and roofing industries looking to enhance their production capabilities. These machines are sophisticated pieces of engineering designed to craft metal roofing tiles precisely and efficiently, meeting the high demand for durable roofing solutions.

Installing and maintaining these machines is often supported by comprehensive training and after-sales programs offered by reputable manufacturers. These programs empower operators with the knowledge to troubleshoot minor issues independently and conduct routine maintenance. Furthermore, having established channels of support ensures that any significant issues can be addressed promptly, minimizing disruption to the production process. Energy efficiency is another critical aspect of modern roofing tile roll forming machines. As more businesses strive to minimize their environmental impact, choosing machines that consume less power without compromising on performance becomes essential. Energy-efficient designs not only reduce the operational carbon footprint but also bring down utility costs, adding significant value to long-term investments. In terms of trustworthiness and industry standing, it is immensely beneficial to purchase from manufacturers who have a proven track record. Established companies that have supplied roofing solutions to a wide range of clients demonstrate reliability and expertise. Certifications and compliances with international standards further bolster the credibility of these machines, assuring buyers they are making a sound investment. Investing in a roofing tile roll forming machine is a strategic decision that can propel a business forward, enabling high-quality production while ensuring cost-efficiency and sustainability. By focusing on precision, versatility, durability, and energy efficiency, companies can find a machine tailored to their specific needs, thereby unlocking the full potential of their production capabilities.

Installing and maintaining these machines is often supported by comprehensive training and after-sales programs offered by reputable manufacturers. These programs empower operators with the knowledge to troubleshoot minor issues independently and conduct routine maintenance. Furthermore, having established channels of support ensures that any significant issues can be addressed promptly, minimizing disruption to the production process. Energy efficiency is another critical aspect of modern roofing tile roll forming machines. As more businesses strive to minimize their environmental impact, choosing machines that consume less power without compromising on performance becomes essential. Energy-efficient designs not only reduce the operational carbon footprint but also bring down utility costs, adding significant value to long-term investments. In terms of trustworthiness and industry standing, it is immensely beneficial to purchase from manufacturers who have a proven track record. Established companies that have supplied roofing solutions to a wide range of clients demonstrate reliability and expertise. Certifications and compliances with international standards further bolster the credibility of these machines, assuring buyers they are making a sound investment. Investing in a roofing tile roll forming machine is a strategic decision that can propel a business forward, enabling high-quality production while ensuring cost-efficiency and sustainability. By focusing on precision, versatility, durability, and energy efficiency, companies can find a machine tailored to their specific needs, thereby unlocking the full potential of their production capabilities.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products