Top Manufacturers of Roofing Tile Forming Machines for Quality Production Solutions

The Role of Roofing Tile Forming Machine Manufacturers in the Construction Industry

In the contemporary construction landscape, roofing materials play a pivotal role in ensuring the durability and aesthetic appeal of buildings. Among the various types of roofing materials, tiles have been favored for their strength, longevity, and diverse design options. To meet the growing demand for high-quality roofing tiles, the importance of roofing tile forming machine manufacturers cannot be overstated. These manufacturers are integral to the production process, providing innovative machinery that enhances quality, efficiency, and sustainability.

Understanding Roofing Tile Forming Machines

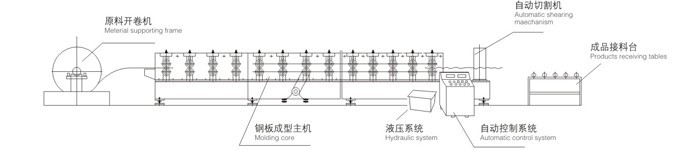

Roofing tile forming machines are specialized equipment designed to convert raw materials into finished roofing tiles. These machines use advanced technologies to mold and shape various types of materials, including clay, concrete, and metal, into tiles that can withstand harsh weather conditions. The production cycle typically includes processes such as material feeding, molding, cutting, and drying. Each step requires precision and reliability to ensure that the final products meet industry standards.

Advancements in Technology

Roofing tile forming machine manufacturers are at the forefront of technological innovations. The latest machines are equipped with Computer Numerical Control (CNC) systems, which allow for automated and precise production processes. This level of automation not only increases productivity but also minimizes human error, resulting in uniformity and superior quality in roofing tiles.

Moreover, many manufacturers are embracing the Internet of Things (IoT) and Artificial Intelligence (AI) in their machinery. These technologies enable real-time monitoring of production processes, predictive maintenance, and operational efficiency. By incorporating these advancements, manufacturers can reduce downtime and production costs while improving the overall quality of the tiles produced.

Sustainability and the Environment

As global awareness of environmental issues increases, roofing tile forming machine manufacturers are responding by adopting sustainable practices. Many manufacturers are now focusing on the use of eco-friendly materials and processes. For instance, the production of tiles from recycled materials is becoming more prevalent, significantly reducing waste.

roofing tile forming machine manufacturers

Additionally, energy-efficient machines are being designed to minimize energy consumption during production

. These efforts not only contribute to reducing the carbon footprint of the industry but also aid manufacturers in complying with increasingly stringent environmental regulations.Customization and Design Flexibility

One of the significant advantages of roofing tile forming machines is their ability to produce customized tiles. Manufacturers can design machines capable of creating tiles in various shapes, sizes, and colors to meet specific architectural needs. This flexibility allows builders and architects to explore more creative designs, enhancing the overall look of residential and commercial buildings.

Furthermore, the capability to produce small batches of custom designs means that even niche markets can thrive. Roofing tile forming machine manufacturers enable local producers to cater to regional aesthetics and preferences, promoting local craftsmanship.

Economic Impact

The roofing tile forming machine industry not only meets the demands of the construction sector but also plays a vital role in the economy. By providing machinery and technology, manufacturers support local tile production businesses, contributing to job creation and economic growth. Additionally, with the rise of new markets and construction trends, the demand for roofing tile forming machines is expected to continue increasing, further driving economic development.

Conclusion

In conclusion, roofing tile forming machine manufacturers are crucial players in the construction industry. Their commitment to technological advancements, sustainability, customization, and economic growth underscores their importance. As the demand for high-quality and environmentally friendly roofing solutions continues to rise, these manufacturers will undoubtedly remain at the heart of the industry, shaping the future of roofing tile production. As the sector evolves, innovations from these manufacturers will continue to pave the way for more efficient, sustainable, and aesthetically pleasing roofing solutions, benefiting builders and homeowners alike.

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025