roofing sheets manufacturing machine price

The Cost of Roofing Sheets Manufacturing Machines An Insight into the Industry

In the construction industry, roofing sheets play a crucial role, providing essential protection against various weather conditions while enhancing the aesthetic appeal of buildings. The demand for durable and efficient roofing solutions has propelled the growth of roofing sheets manufacturing, leading to increased interest in the machinery used for production. Understanding the pricing dynamics of roofing sheets manufacturing machines is vital for investors, manufacturers, and contractors alike.

The Types of Roofing Sheets Manufacturing Machines

Before delving into pricing, it's important to recognize the types of machines involved in roofing sheets manufacturing. Generally, these machines can be categorized into three types

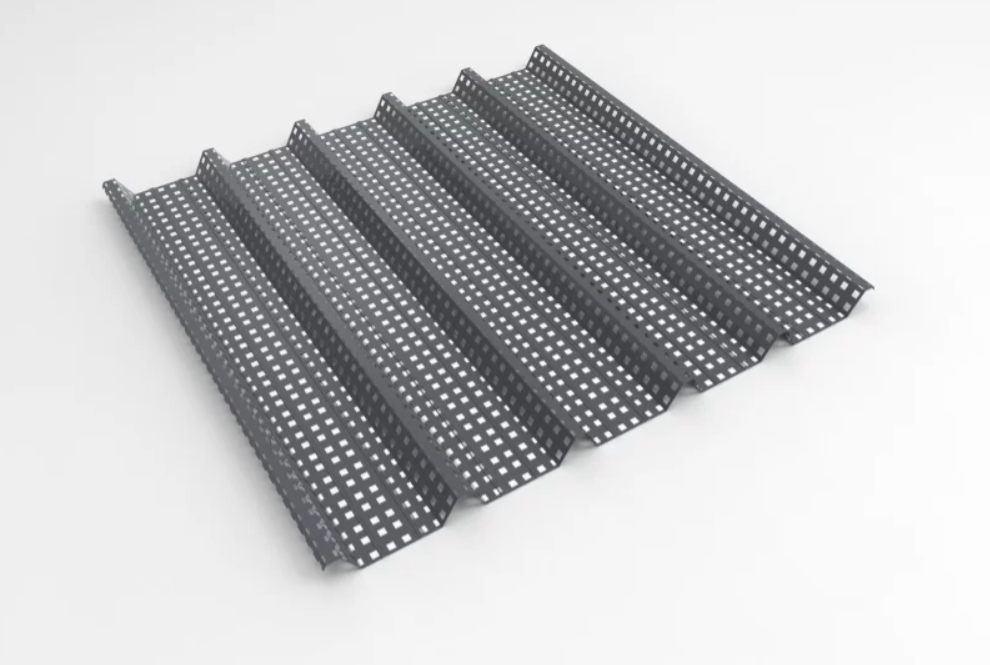

1. Roll Forming Machines These machines are designed to create shaped metal sheets by passing flat metal strips through a series of rollers. The cost of roll forming machines varies widely based on their capacity, size, and the complexity of the profiles they can produce.

2. Cutting Machines These machines are used to cut the roofing sheets to specific lengths after they have been formed. While cutting machines may seem straightforward, advanced models equipped with automation technology will be costlier.

3. Coating Lines For sheets to resist corrosion and adhere better to paint, coating lines are installed to apply protective layers. These systems are generally more expensive due to the advanced technology involved.

Price Range of Roofing Sheets Manufacturing Machines

On average, the price for roofing sheets manufacturing machines can range significantly, typically from $20,000 to over $500,000, depending on various factors

roofing sheets manufacturing machine price

- Machine Type and Complexity Basic roll forming machines may start at around $20,000, while fully automated and high-capacity machines can range from $100,000 to $500,000 or more.

- Capacity and Output Machines designed for high production volumes generally come with a higher price tag. A machine that can produce thousands of sheets per hour might incur additional costs due to the engineering and materials involved.

- Customization Many manufacturers offer tailored solutions to meet specific operational needs. Customization usually leads to increased costs due to the additional engineering and manufacturing processes involved.

- Brand and Reliability Established brands often command a premium due to their reputation and reliability. Investing in machinery from a well-regarded manufacturer can provide assurance regarding the quality and longevity of the equipment.

Factors Influencing Costs

Several factors affect the pricing of roofing sheets manufacturing machines. One crucial element is technological advancements. With the rise of automation and smart technology, machines that feature advanced controls and monitoring systems come at a premium. Such investments can lead to increased efficiency, reduced waste, and lower labor costs, which may offset the initial cost over time.

Another factor is geographic location. Prices may vary based on shipping costs, import duties, and local market conditions. In regions where construction is booming, demand for production machinery can drive prices upward.

Conclusion

The investment in roofing sheets manufacturing machines is significant, but understanding the price dynamics is essential for making informed decisions. Potential buyers should consider the type of machine best suited for their needs, evaluate the long-term benefits of different models, and keep an eye on market trends that might influence costs. By carefully assessing these factors, manufacturers can position themselves for success in an increasingly competitive industry, ultimately contributing to the thriving construction sector. As technology evolves, staying informed about pricing and advancements will be key for anyone looking to invest in roofing sheets manufacturing machinery.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025