Affordable Roofing Sheet Roll Forming Machines from Reliable Factories

Understanding the Price Dynamics of Roofing Sheet Roll Forming Machines

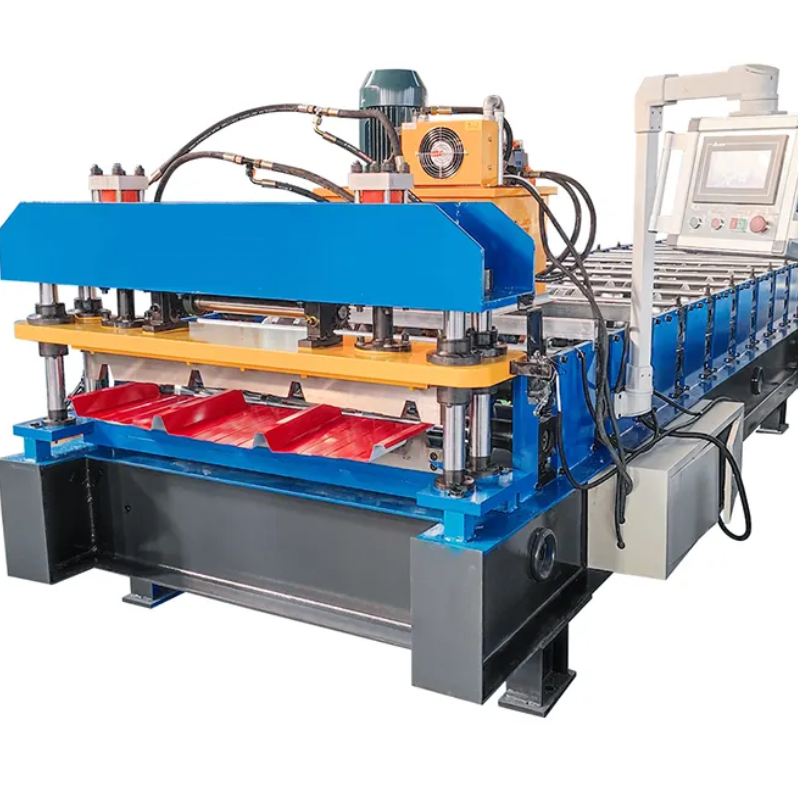

In the construction and manufacturing industries, having the right machinery is crucial for efficiency and productivity. One such essential machinery is the roofing sheet roll forming machine. This machine is pivotal in producing roofing sheets that are widely used in residential, commercial, and industrial buildings. With the increasing demand for these roofing sheets, prospective buyers are often keen to understand the various factors that influence the price of roofing sheet roll forming machines from factories.

What is a Roofing Sheet Roll Forming Machine?

A roofing sheet roll forming machine is designed to convert metal coils into roofing sheets through a series of gradual, precise processes. The machine uses rollers to shape the metal into the desired profile, which can vary depending on the intended application. These machines are capable of producing various types of roofing sheets, including corrugated, tile, and trapezoidal profiles, making them versatile tools for manufacturers.

Factors Influencing Price

1. Material Quality The type of materials used in constructing the machine significantly affects its price. Higher quality materials will typically result in a more durable and reliable machine, leading to a higher initial investment.

2. Machine Specifications The complexity and capabilities of the machine contribute to price variations. Machines with advanced features, such as automated controls, programmable functions, and higher production speeds, will generally command a higher price than basic models.

roofing sheet roll forming machine price factory

3. Production Capacity The output capacity of a roofing sheet roll forming machine plays a crucial role in pricing. Machines that can produce larger volumes of sheets in a shorter period are often more expensive due to their efficiency and productivity.

4. Manufacturer Reputation The credibility and reputation of the manufacturing factory can also impact pricing. Established brands with a track record of quality and customer satisfaction may charge higher prices for their equipment compared to lesser-known manufacturers.

5. Customization Many manufacturers offer customization options to meet specific client needs. Customized machines may entail additional costs due to their tailored features, which can affect the overall pricing.

6. Market Trends Economic factors and market demand also influence equipment pricing. When demand for roofing sheets is high, prices for manufacturing machines may rise correspondingly.

Conclusion

For businesses looking to invest in a roofing sheet roll forming machine, understanding the various factors that influence pricing is crucial. While the initial cost may seem daunting, considering the long-term benefits in terms of efficiency and quality production is essential. Potential buyers should perform thorough research, compare multiple manufacturers, and assess their specific needs before making a purchase. By doing so, they can find a machine that not only fits their budget but also contributes to their overall operational success in the competitive roofing industry.

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025