Roofing Sheet Production Equipment Manufacturing Solutions and Innovations

The Importance of Roofing Sheet Profiling Machine Factories

In the modern construction industry, the demand for durable and aesthetically pleasing roofing materials is ever-increasing. Roofing sheet profiling machines play a critical role in the production of roofing sheets that meet the diverse needs of builders and architects alike. Establishing a factory dedicated to these machines is a significant investment, with long-term benefits for both manufacturers and end-users.

A roofing sheet profiling machine is designed to transform raw metal sheets into various profiles that cater to different roofing requirements. These methods not only provide structural integrity but also enhance the visual appeal of buildings. Factories that specialize in this type of machinery are pivotal in ensuring that high-quality roofing sheets are produced efficiently and consistently.

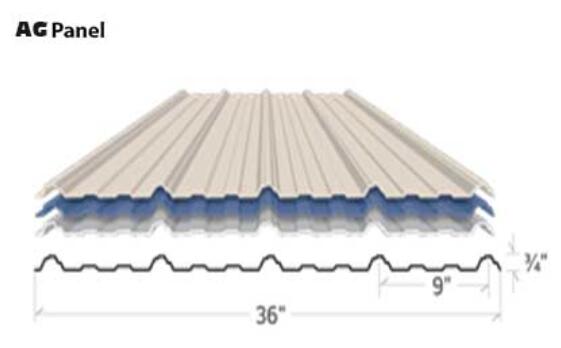

The operation of a roofing sheet profiling machine involves several processes, including coil feeding, roll forming, and cutting. The precision engineering of these machines allows them to produce sheets in various profiles, such as corrugated, trapezoidal, or custom designs. This versatility is essential for meeting the unique demands of different construction projects. By investing in advanced technology, factories can produce roofing sheets that are not only reliable but also environmentally friendly, utilizing recyclable materials whenever possible.

roofing sheet profiling machine factory

Moreover, roofing sheet profiling machine factories contribute significantly to local economies. They create job opportunities, from factory workers to engineers and sales personnel. By fostering skilled labor, these factories help boost innovation in manufacturing processes and improve product quality. Additionally, the production of roofing sheets within a local factory reduces transportation costs and times, making them more accessible to nearby construction projects.

On a global scale, roofing sheet profiling machine manufacturers are also positioned to capitalize on the growing trend of sustainable building practices. With an increasing focus on energy efficiency and eco-friendly materials, factories are adopting practices that align with these values. By offering roofing sheets that incorporate energy-saving features, such as reflective coatings or green roofing solutions, these factories can cater to a market that prioritizes sustainability.

In conclusion, roofing sheet profiling machine factories represent a critical component of the construction industry. They not only produce high-quality roofing materials but also contribute to economic growth and environmental sustainability. As building practices evolve, the role of these factories will become increasingly vital, serving both the immediate local demand and the broader trends in sustainable architecture. Investing in roofing sheet profiling machine technology is not just a business decision; it is a commitment to building a better future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025