Prices of Roofing Sheet Manufacturing Machines from Various Factories

Understanding the Costs of Roofing Sheet Manufacturing Machines

In the construction and building maintenance industry, roofing sheets play a pivotal role in safeguarding structures from external elements. As the demand for high-quality roofing materials continues to rise, the need for efficient manufacturing processes has become paramount. This has led to an increase in the developing and investing in roofing sheet manufacturing machines. However, businesses must navigate the complexities of pricing when considering these investments.

The Importance of Roofing Sheet Manufacturing Machines

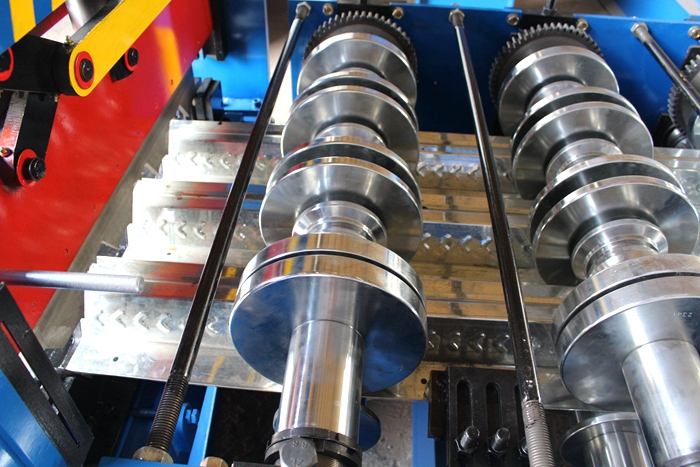

Roofing sheet manufacturing machines are pivotal in producing a variety of roofing materials, including metal, plastic, and composite sheets. These machines are designed to achieve high efficiency, uniform quality, and scalability in production. They usually come equipped with advanced technology that ensures precision in cutting, shaping, and finishing the roofing sheets. By automating production, manufacturers can significantly reduce labor costs, minimize material waste, and maintain consistent quality standards.

Factors Influencing the Price of Roofing Sheet Manufacturing Machines

The price of roofing sheet manufacturing machines can vary significantly based on several factors

1. Type of Machine Different types of machines cater to different materials and production scales. For instance, a basic roll-forming machine may cost significantly less than an advanced automated production line that includes printing and cutting capabilities.

2. Production Capacity Machines with higher production capacities tend to be more advanced and, consequently, more expensive. A business's requirements — whether it's for small-scale or industrial-scale production — heavily influence the choice of machinery and its cost.

3. Technology and Features The integration of advanced technologies, such as computer numerical control (CNC), digital displays, and automated quality control systems, can increase the machine's price but also enhance productivity and efficiency.

4. Brand and Manufacturer Reputation Established brands often command higher prices due to their reputation for quality and reliability. However, investing in a reputable machine can yield long-term savings through durability and fewer repairs.

roofing sheet manufacturing machine price factories

5. Geographical Location The location of the manufacturing factory can impact shipping costs, import taxes, and tariffs, influencing the final price. Local manufacturers may offer lower prices due to reduced transportation costs compared to overseas suppliers.

6. Customization Custom-built machines tailored to specific production needs can significantly affect pricing. While standard machines may be more affordable, customization can enhance production efficiency and meet particular business requirements.

An Overview of Price Ranges

While prices can vary greatly, it is possible to categorize roofing sheet manufacturing machines into general price ranges. Entry-level machines suitable for small production runs can be found for as little as $10,000. Mid-range machines often cost between $25,000 to $50,000 and are suitable for medium-scale operations. High-end, fully automated systems can run up to $200,000 or more, offering extensive capabilities that cater to large manufacturers.

Making an Informed Decision

Investing in a roofing sheet manufacturing machine is a significant financial commitment. Therefore, it’s essential for business owners to conduct thorough research and consider their specific needs. Engaging with manufacturers, requesting quotes, and reviewing machine specifications are crucial steps in making an informed choice.

Additionally, potential buyers should assess the long-term benefits, such as reduced labor costs, improved production speeds, and lower material wastage versus the initial expenditure. Analyzing the return on investment (ROI) can help in justifying the purchase of more expensive machinery that will enhance productivity and profitability.

Conclusion

As the construction industry continues to evolve, the demand for efficient and reliable roofing sheet manufacturing machines is likely to increase. Understanding the various factors that influence their price can aid businesses in making informed purchasing decisions. Whether it's a small startup or an established manufacturing entity, investing in the right roofing sheet manufacturing machine can lead to significant operational benefits and drive competitive advantage in the market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025