roofing sheet making machine price factory

The Comprehensive Guide to Roofing Sheet Making Machine Prices and Factories

In the modern construction industry, the necessity for high-quality roofing materials is paramount. Roofing sheets serve a crucial role in protecting buildings from weather elements while providing aesthetic appeal. The manufacturing of roofing sheets has evolved significantly with technological advancements, leading to the rise of modern roofing sheet making machines. This article explores the factors influencing the prices of these machines, the various factories involved, and what to consider when investing in one.

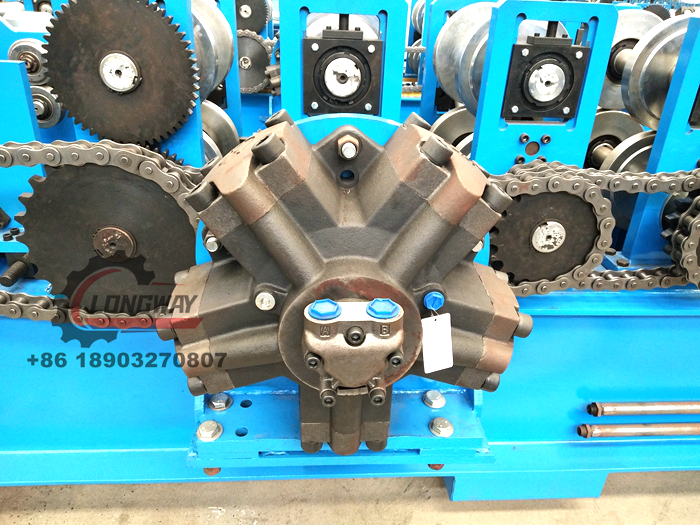

Understanding Roofing Sheet Making Machines

Roofing sheet making machines are specialized equipment designed to produce various types of roofing sheets from different materials like metal, PVC, and more. These machines come equipped with advanced technology, ensuring efficiency and precision in production. They are capable of producing sheets in various shapes, sizes, and thicknesses to meet diverse customer needs.

Factors Influencing Prices

1. Type of Machine There are different models of roofing sheet making machines available in the market, ranging from manual to fully automated systems. While manual machines are relatively inexpensive, they may not offer the speed and efficiency of their automated counterparts, which tend to be pricier.

2. Material Used The materials that the machine can handle also affect its pricing. Machines that can work with multiple materials, like metal or synthetic options, generally come at a higher cost due to their versatility and advanced features.

3. Production Capacity The production capacity of the machine plays a significant role in determining its price. Machines that can produce larger quantities in shorter times are usually more expensive, as they cater to high-demand production requirements.

4. Technology and Features Advanced technologies such as computerized controls, automatic feeding systems, and integrated cutting mechanisms increase a machine's price. These features not only enhance efficiency but also minimize waste and production time.

5. Brand and Manufacturer The reputation of the manufacturer can also influence the price. Established brands might charge a premium for their machines due to perceived reliability and quality, while new or lesser-known manufacturers may offer more competitive pricing.

roofing sheet making machine price factory

6. Geographic Location Pricing can vary by region due to factors such as shipping costs, import tariffs, and local manufacturing expenses. Buyers should consider these factors to assess the overall cost-effectiveness.

Finding the Right Factory

When searching for roofing sheet making machines, it's essential to consider the factory where the machines are produced. Here are some points to keep in mind

1. Reputation Research the factory's reputation within the industry. Look for reviews and testimonials from previous customers to gauge the quality of the machines and after-sales service.

2. Production Capacity Ensure that the factory has the capability to meet your production needs. A factory with a higher production capacity may be better suited for large-scale operations.

3. Customization Options Some factories offer customization options for machines, which can be beneficial if you have specific requirements for your roofing sheets.

4. After-Sales Support Excellent after-sales support is crucial for smooth operations. Choose a factory that provides comprehensive maintenance services and readily available spare parts.

5. Warranty and Return Policy A good warranty and a favorable return policy signify confidence in the product. This protection can save you money and hassle in case of unexpected issues.

Conclusion

Investing in a roofing sheet making machine is a significant decision that can greatly enhance your construction or manufacturing business. Understanding the factors affecting pricing and taking the time to find the right factory can lead to fruitful outcomes. By doing thorough research and choosing wisely, you can ensure that you acquire a machine that not only meets your production needs but also offers excellent quality and reliability. Whether you’re a small business owner or part of a large construction company, making an informed decision about roofing sheet making machines will undoubtedly pave the way for your future success.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025