roofing sheet making machine manufacturer

The Future of Roofing Sheet Making Machines A Manufacturer’s Perspective

In the construction industry, roofing materials play a crucial role in ensuring the durability, energy efficiency, and aesthetic appeal of buildings. Roofing sheet making machines have revolutionized the way these essential materials are produced, and as a result, the demand for advanced manufacturing solutions has soared. As a leading manufacturer of roofing sheet making machines, we are committed to innovation, quality, and customer satisfaction.

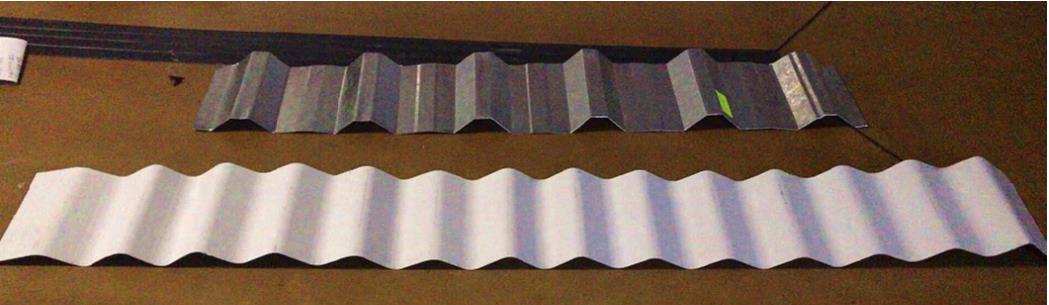

Roofing sheet making machines are designed to produce various types of sheets, including corrugated, trapezoidal, and tiles-like profiles, using diverse raw materials such as galvanized steel, aluminum, and PVC. The production process involves several key steps, including decoiling, feeding, roll forming, cutting, and stacking. With advancements in technology, these machines have become more efficient, offering higher production speeds, better precision, and reduced waste.

Innovation and Technology

At the heart of our roofing sheet making machines lies cutting-edge technology. The integration of computer numerical control (CNC) systems allows for enhanced automation and precision, which significantly reduces the margin for error in production. Additionally, the use of high-quality materials in the construction of these machines ensures they can withstand the rigors of continuous operation, thereby increasing their lifespan and reliability.

Furthermore, our machines are equipped with advanced safety features to protect operators and ensure compliance with industry regulations

. Safety sensors, emergency stop buttons, and protective enclosures are standard in our machine designs, reflecting our commitment to creating a safe working environment.Customization to Meet Client Needs

roofing sheet making machine manufacturer

Understanding that every client has unique requirements, we offer a range of customizable options for our roofing sheet making machines. Clients can choose from different production capacities, machine sizes, and specific features to meet their needs. Whether it’s a small-scale operation or a large manufacturing facility, we have solutions tailored to each business’s demands.

Moreover, our design team collaborates closely with clients to understand their production goals and assist them in selecting the right machine configuration. This level of personalized service sets us apart in the competitive market of roofing sheet manufacturing.

Support and After-Sales Services

We believe that our responsibility to our clients extends beyond the sale of our machines. Our dedicated support team provides comprehensive after-sales services, including installation, training, and maintenance. We understand that any downtime can be costly, so we are committed to ensuring our machines operate smoothly and efficiently.

Training sessions for operators are crucial to maximizing productivity and minimizing errors. We offer in-depth training on machine operation, troubleshooting, and preventive maintenance to empower our clients and enhance their workforce capabilities.

Conclusion

The roofing sheet making machine industry is evolving rapidly, driven by technological advancements and increasing demand for high-quality building materials. As a leading manufacturer, we are excited about the opportunities this presents. Our focus on innovation, customization, and exceptional customer service positions us to meet the challenges of the future head-on. By investing in our machines, clients are not only enhancing their production capabilities but also securing a competitive edge in the market. Whether you are looking to expand your production line or start a new venture, partnering with us will help you achieve your goals in roofing sheet manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025