Roofing Roll Forming Machines Price Comparison for Manufacturers and Buyers

Understanding Roofing Roll Forming Machine Prices and Manufacturers

In the modern manufacturing landscape, the demand for quality roofing materials has led to a significant rise in the use of roofing roll forming machines. These machines are essential for producing metal roof panels and other essential components in the roofing industry. As more manufacturers enter the market, understanding the pricing and the factors influencing the costs of these machines is critical for businesses looking to invest wisely.

What is a Roofing Roll Forming Machine?

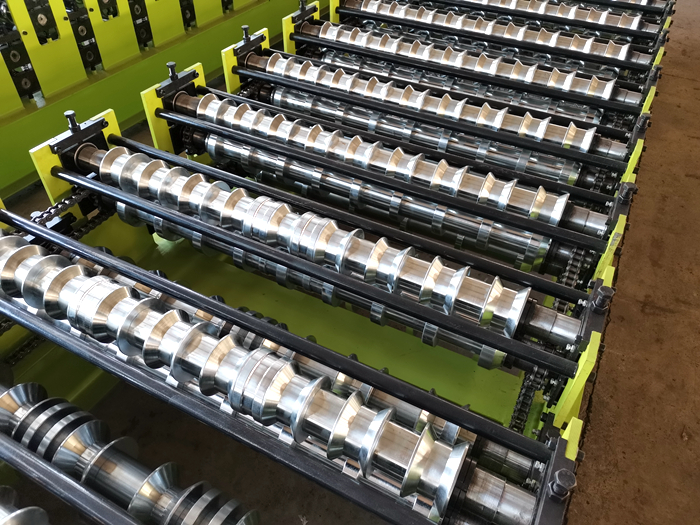

A roofing roll forming machine is a type of industrial equipment designed to produce metal roofing sheets from coiled metal. The process involves feeding a coil into the machine, where it is shaped and molded through a series of rollers. The resulting products can vary widely, from simple corrugated sheets to more complex profiles tailored for specific applications. The efficiency and precision of these machines make them indispensable in the construction and roofing industries.

Pricing Factors

When considering the purchase of a roofing roll forming machine, several factors can influence its price

1. Machine Specifications The complexity of the machine and the types of profiles it can produce are significant factors. Basic models are generally cheaper, while more advanced machines that offer a range of features, high-speed production, and custom capabilities tend to be more costly.

2. Material Compatibility Machines designed to work with various metals, such as aluminum, steel, and zinc, may come at a higher price point. Additionally, models that can handle different thicknesses and coil widths will have more sophisticated features, impacting the cost.

3. Production Capacity High-capacity machines that can produce large volumes at a faster rate are generally more expensive. Businesses with high demand may find it worthwhile to invest in faster, more efficient machines despite the higher upfront costs.

4. Manufacturer Reputation Established manufacturers with a proven track record for quality and reliability tend to charge premium prices. However, investing in a reputable brand can lead to better support, longer warranties, and more reliability in the long term.

roofing roll forming machine price manufacturers

5. Customization Options Many businesses require specific configurations to meet their unique needs. Custom machines may come at a higher price but can ultimately save money by reducing waste and increasing production efficiency.

6. Location and Logistics The geographical location of the manufacturer can also affect pricing. Transportation costs, local tariffs, and import duties can significantly impact the final price of the machinery.

Major Manufacturers in the Market

As the market for roofing roll forming machines expands, several key players stand out due to their quality, innovation, and customer service

1. China-based Manufacturers Many of the world’s roofing roll forming machines are produced in China, where manufacturers like Huazhong Machinery and Zhongtuo utilize advanced technology to offer competitive pricing. These companies are known for their extensive customization options and efficient production capabilities.

2. European Manufacturers Companies such as Mikkeli and FATA Alu offer high-quality machines with a focus on reliability and precision. While they might come at a higher expense due to advanced engineering standards, they are often preferred for specialized applications.

3. North American Brands Brands like New Tech Machinery and A.C.T. Metal Deck Supply cater to the North American market, focusing on facilities that require durable and efficient machines. Their emphasis on customer service and part availability makes them popular choices despite sometimes higher prices.

Conclusion

Investing in a roofing roll forming machine is a significant decision that can greatly impact a business's productivity and profitability. Understanding the various factors that influence the pricing and carefully evaluating different manufacturers will help businesses make informed choices. Whether opting for a budget-friendly model or a premium machine with advanced features, the key is to consider the long-term benefits and return on investment. As the demand for quality roofing solutions continues to grow, investing in the right machinery will ensure competitive advantage and operational excellence.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025