roofing roll forming machine price manufacturers

Understanding the Pricing of Roofing Roll Forming Machines A Comprehensive Guide

In the world of construction and manufacturing, efficiency and precision are paramount. Roofing roll forming machines play a significant role in fabricating various types of metal roofing, an integral aspect of modern architecture. When considering the purchase of a roofing roll forming machine, many factors come into play, particularly its price and the manufacturers behind these machines. This article delves into the aspects that influence the pricing of roofing roll forming machines and highlights key manufacturers in the industry.

What is a Roofing Roll Forming Machine?

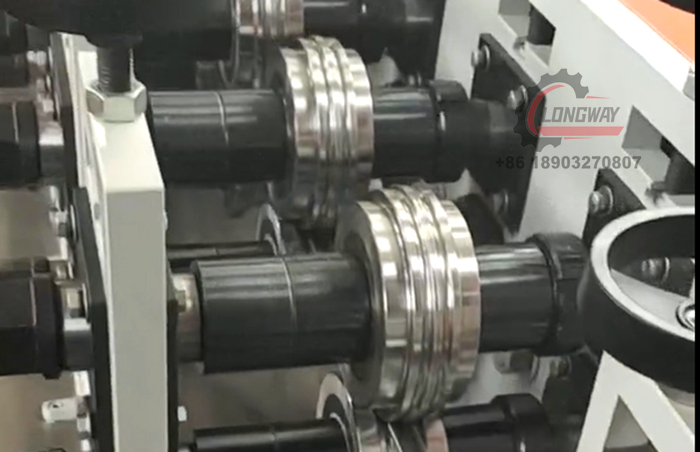

A roofing roll forming machine is a specialized piece of equipment designed to produce roofing panels and sheets by transforming metal strips into the desired shapes. These machines take flat sheets of metal and pass them through a series of rollers, shaping the metal into usable profiles. The key advantages of using roll forming technology include high material efficiency, uniformity in product quality, and the ability to produce complex designs with minimal manual intervention.

Factors Influencing the Price of Roofing Roll Forming Machines

1. Machine Specifications The price of a roofing roll forming machine can vary significantly based on its specifications. High-capacity machines that can handle thicker materials or larger production volumes will naturally cost more. Features such as the number of forming stations, the roller material (hardening treatments), and the overall build quality contribute to the final price.

2. Customization Options Many manufacturers offer custom solutions to cater to specific customer needs, such as unique profiles or automated features. Customization can lead to increased costs, as it often involves additional engineering and manufacturing processes.

3. Technology and Automation Advanced technologies, including CNC (Computer Numerical Control) systems and automation, can enhance productivity and precision. While these innovations can lead to higher initial costs, they often result in lower operational costs and increased efficiency in the long run.

4. Brand Reputation The reputation of the manufacturer and the quality of their products can significantly impact pricing. Established brands with a history of quality and reliability tend to charge a premium, as their machines are often seen as a worthwhile investment due to their longevity and performance.

roofing roll forming machine price manufacturers

5. Geographic Location The location of both the manufacturer and the buyer can affect pricing due to shipping costs, taxes, and tariffs. Importing a machine from an overseas manufacturer might be cheaper initially but can incur additional costs in shipping and customs fees.

6. After-Sales Support Comprehensive after-sales support, including installation, maintenance, and training, is crucial but can also add to the initial price. Manufacturers who provide extensive customer service and support packages may charge higher prices but offer peace of mind as part of the deal.

Leading Manufacturers of Roofing Roll Forming Machines

1. China National Building Material Group Corporation (CNBM) One of the largest building materials companies in China, CNBM specializes in various manufacturing machinery, including roofing roll forming machines. They are known for their competitive pricing and extensive range of products.

2. Kleemann This German manufacturer is recognized for its high-quality machinery and innovative designs, focusing on efficiency and precision. While their machines may be priced at a premium, they are considered a worthwhile investment for large-scale operations.

3. Tecno Systems An Italian company, Tecno Systems offers a diverse range of roll forming machines with a focus on customization to meet specific customer needs. Their reputation for quality and technology integration makes them a popular choice in Europe and beyond.

4. RoboVent Known for their robust machines that prioritize safety and environmental considerations, RoboVent provides solutions that are tailored for modern manufacturing demands. Their commitment to sustainability is becoming increasingly relevant in the industry.

Conclusion

Investing in a roofing roll forming machine is a significant decision for any construction or manufacturing business. Understanding the factors that influence the pricing, such as machine specifications, customization options, and the reputation of manufacturers, is crucial for making an informed choice. With a better grasp of these elements, prospective buyers can confidently navigate the market, ensuring they select a machine that not only meets their production needs but also fits within their budget. As the demand for quality roofing materials continues to rise, the importance of choosing the right roll forming machine cannot be overstated.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025