Roof Sheet Production Equipment for Efficient Construction and Custom Design Solutions

The Roof Forming Machine An Essential Tool for Modern Construction

In the world of construction, efficiency and precision are paramount. One of the most innovative tools that have made significant strides in this field is the roof forming machine. This machine is designed to streamline the process of creating roofing materials, ensuring that buildings are not only structurally sound but also visually appealing. With advancements in technology, roof forming machines have become essential for modern construction projects.

What is a Roof Forming Machine?

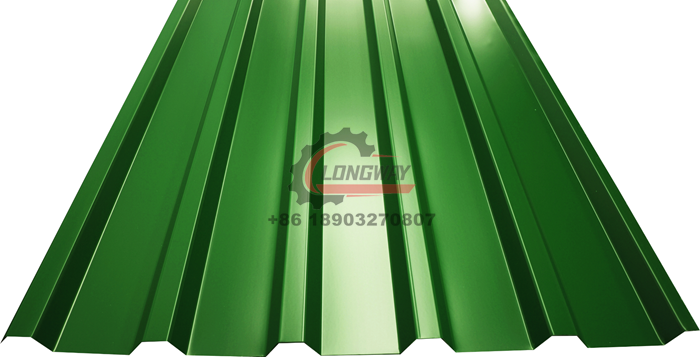

A roof forming machine is a specialized piece of equipment used to create metal roofing sheets. These machines can transform flat sheets of metal into corrugated, ribbed, or other desired profiles that suit various architectural styles. They are capable of producing a wide range of dimensions and thicknesses, making them versatile for different building requirements. Typically, these machines operate on the principle of continuous forming, where a roll of metal is fed through a series of rollers that gradually shape it into the final profile.

Types of Roofing Profiles

Roof forming machines can produce various profiles, catering to different aesthetic and functional requirements. Some common types of roofing profiles include

1. Corrugated Panels These are among the most popular roofing materials due to their strength and ability to channel water effectively. Corrugated panels are often used in agricultural buildings, industrial structures, and residential homes.

2. Standing Seam Panels Known for their sleek appearance, standing seam roofs are characterized by vertical seams that interlock. This design not only enhances the roof's durability but also provides an elegant finish, making it a favorite for modern architectural designs.

4. Flat Panels Ideal for contemporary design, flat panels offer a minimalist look and are widely used in commercial and residential buildings.

roof forming machine

Advantages of Using a Roof Forming Machine

1. Efficiency The automation and speed of roof forming machines significantly reduce production time. What used to take hours or even days can now be accomplished in a matter of minutes.

2. Cost-Effective By cutting down on labor costs and reducing material waste through precision manufacturing, roof forming machines can ultimately save money over the life of a project.

3. Customization Many modern roof forming machines come with features that allow for easy adjustments to produce customized roofing profiles. This adaptability makes them suited for a range of projects from residential homes to large commercial buildings.

4. Durability The roofing materials produced by these machines are often more resilient and long-lasting compared to traditional roofing materials, thanks to advanced manufacturing processes and high-quality materials used.

5. Reduced Waste Precision in cutting and forming reduces the amount of scrap material generated during the production process, promoting more sustainable construction practices.

Conclusion

The roof forming machine is a vital piece of equipment in the construction industry, providing builders with the ability to produce high-quality, custom roofing materials efficiently and cost-effectively. As architectural designs continue to evolve, the need for versatile and precise roofing solutions grows. By investing in state-of-the-art roof forming machines, companies can not only enhance their competitiveness in the market but also contribute to the sustainability of construction practices.

In a world where time is of the essence and quality cannot be compromised, the roof forming machine stands out as a testament to innovation. As we move forward, embracing new technologies in construction will pave the way for smarter, more efficient practices, ensuring that buildings are both functional and aesthetically pleasing. The evolution of roof forming machines is a significant step in this direction, providing the necessary tools for constructing the roofs of tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025