roof cladding roll forming machine

The Importance of Roof Cladding Roll Forming Machines in Modern Construction

In the ever-evolving landscape of construction technology, roof cladding roll forming machines have emerged as essential tools for manufacturers and builders. These advanced machines play a pivotal role in creating durable, efficient, and aesthetically pleasing roofing solutions that cater to diverse architectural needs. This article delves into the significance of roof cladding roll forming machines, their advantages, and their applications in modern construction.

Understanding Roof Cladding Roll Forming Machines

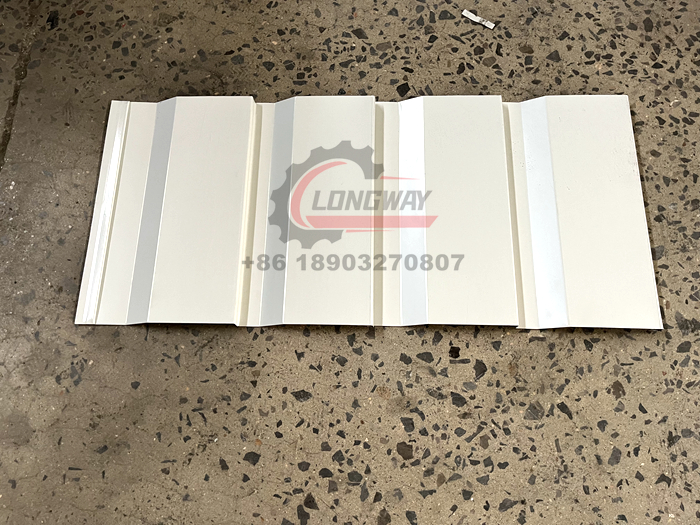

Roof cladding roll forming machines are specialized equipment designed to process metal sheets into specific profiles required for roofing applications. These machines utilize a continuous forming process, where a flat metal coil is gradually formed into desired shapes through a series of rollers. This method ensures consistency, precision, and efficiency in producing various roofing profiles such as corrugated sheets, standing seam panels, and trapezoidal designs.

Key Advantages of Roof Cladding Roll Forming Machines

1. Efficiency and Speed One of the primary advantages of using roll forming machines is their high production speed. Once set up, these machines can operate continuously, producing large quantities of roofing materials in a fraction of the time it would take using traditional methods. This efficiency not only reduces labor costs but also meets the demanding timelines of construction projects.

2. Precision and Consistency Roll forming ensures that each piece of roofing material is produced to exact specifications. The automated nature of these machines minimizes the risk of human error, resulting in uniform products that fit perfectly during installation. This precision is crucial for maintaining the structural integrity and weatherproofing of roofs.

3. Material Versatility Roof cladding roll forming machines can work with various materials, including galvanized steel, aluminum, and zinc alloy. This versatility allows manufacturers to cater to different market needs and preferences, whether a project requires lightweight metal panels or robust weather-resistant solutions.

4. Cost-Effective Production By streamlining the manufacturing process and reducing material waste, roll forming machines contribute to cost savings. The ability to use coils rather than individual sheets also helps minimize expenses, making it an attractive option for businesses aiming to enhance their profitability.

roof cladding roll forming machine

5. Customization Options Many modern roll forming machines come equipped with advanced technology that allows for easy customization of profiles, lengths, and finishes. This flexibility enables builders to create bespoke roofing solutions that align with specific architectural requirements or aesthetic preferences.

Applications in Modern Construction

Roof cladding roll forming machines have found a wide array of applications in the construction industry. They are predominantly used in commercial buildings, industrial facilities, and residential homes. Here are some common applications

- Industrial Roofing Factories and warehouses often require robust and durable roofing solutions, which can be efficiently produced using roll forming machines. Structures subjected to heavy loads or extreme weather conditions benefit greatly from the strength of metal cladding.

- Commercial Buildings Shopping centers, office buildings, and hotels frequently utilize aesthetically appealing metal roofing. Roll forming machines can create custom designs that enhance the visual appeal while ensuring longevity.

- Residential Roofing Homebuilders increasingly opt for metal roofs due to their durability and energy efficiency. Roll forming technology allows for the production of lightweight yet strong roofing materials that improve a home's insulation and resistance to weather elements.

- Renovation Projects Many renovation projects require matching existing roof profiles. Roll forming machines can produce custom profiles that align with historical features, making them an important resource for restoration work.

Conclusion

Roof cladding roll forming machines are invaluable assets to the modern construction industry. Their ability to produce efficient, high-quality, and customizable roofing solutions positions them as essential equipment for manufacturers and contractors alike. As the demand for innovative and reliable roofing systems continues to grow, these machines will undoubtedly play a crucial role in shaping the future of construction. Embracing this technology not only enhances productivity but also meets the evolving needs of architects, builders, and homeowners across the globe.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025