Roof Batten Roll Forming Equipment Manufacturers for Quality Construction Solutions

Roof Batten Roll Forming Machine Manufacturers A Comprehensive Overview

In the world of modern construction, efficiency and precision are paramount. One of the essential tools that construction companies rely on is the roof batten roll forming machine. This specialized equipment is designed to create roof battens—long, narrow strips of material used to support roofing materials. Given the growing demand for roof batten production, numerous manufacturers have emerged in the market, each offering unique features and innovations.

What is a Roof Batten Roll Forming Machine?

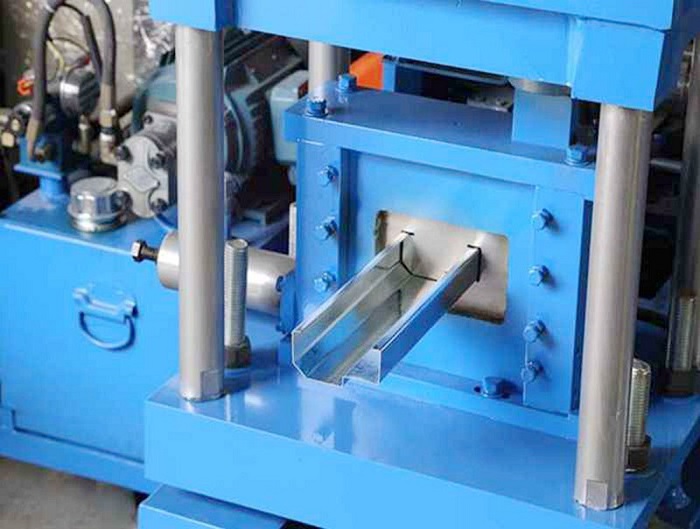

A roof batten roll forming machine uses a series of rollers to shape flat metal sheets into desired profiles for roof battens. The machine operates through a continuous process, taking raw material, often in the form of coils, and feeding it through rollers that progressively form it into battens. The result is a high-strength product tailored to the specifications of various roofing systems, including residential, commercial, and industrial applications.

The Importance of Manufacturers

The choice of a roof batten roll forming machine manufacturer can greatly impact a company’s production efficiency and product quality. Reputable manufacturers provide machines that are not only reliable but also equipped with advanced technology, allowing for automated adjustments, precise measurements, and enhanced durability.

Additionally, manufacturers often offer customization options to tailor the machines to meet specific production needs. This flexibility is particularly important for construction companies that deal with different roofing styles and materials, as it allows them to expand their product offerings without investing in entirely new machinery.

Key Features to Look for in Manufacturers

roof batten roll forming machine manufacturers

When selecting a roof batten roll forming machine manufacturer, there are several important features to consider

1. Quality of Materials High-quality materials in the construction of the machine are crucial for ensuring longevity and reliability. Look for manufacturers that use robust steel frames and premium components.

2. Technology and Innovation Advanced machines come equipped with features such as PLC control systems, which facilitate easy operation and monitoring. Manufacturers that prioritize innovation tend to offer machines that are more efficient and user-friendly.

3. Customization Options As previously mentioned, the ability to customize machines to fit specific production needs is a significant benefit. Reach out to potential manufacturers to discuss custom solutions.

4. After-Sales Support A reliable after-sales support system is essential for minimizing downtime. Manufacturers that provide training, maintenance services, and spare parts support demonstrate a commitment to their customers.

5. Industry Reputation Researching a manufacturer’s reputation within the industry can provide insight into their reliability and the effectiveness of their products. Customer reviews and case studies can be particularly informative.

Conclusion

Choosing the right roof batten roll forming machine manufacturer is crucial for construction companies looking to improve their efficiency and product offerings. By focusing on quality, technological advancement, customization options, and after-sales support, companies can ensure they invest in machinery that meets their needs for years to come. As the construction industry evolves, partnering with a reputable manufacturer can provide a competitive advantage in an ever-changing marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025