roof roll forming machine manufacturers

The Evolution and Importance of Roof Roll Forming Machine Manufacturers

In the construction and manufacturing industry, the efficient production of roofing materials is crucial for both quality and speed. This has led to the rise of roof roll forming machines, a type of equipment that streamlines the process of creating metal roofing panels. As a consequence, roof roll forming machine manufacturers have emerged as key players in meeting the demands for sustainable and cost-effective building solutions.

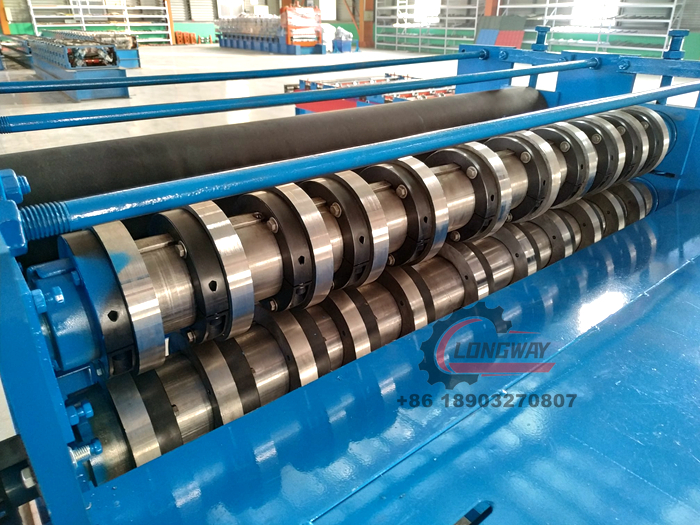

At its core, a roof roll forming machine is designed to convert flat metal sheets into various types of roofing profiles. These machines operate through a series of rollers and stations that progressively shape the metal into the desired form. The versatility of these machines allows for the production of different roofing styles, including standing seam, corrugated sheets, and tile profiles. As a result, manufacturers can cater to a wide range of architectural and construction needs.

One of the significant advantages of using roof roll forming machines is the speed and efficiency of production. Traditional roofing methods often require manual labor for cutting and assembling materials, which can be time-consuming and lead to inconsistencies in quality. In contrast, roof roll forming machines automate much of this process, allowing for continuous production with a high degree of precision. This not only reduces labor costs but also minimizes material waste, making it an environmentally friendly solution.

roof roll forming machine manufacturers

Today's roof roll forming machine manufacturers have invested heavily in technological advancements to enhance their product offerings. Many modern machines are equipped with computer numerical control (CNC) systems that enable operators to program specific profiles, thus ensuring uniformity and precision over large production runs. Moreover, the incorporation of advanced materials and designs has allowed manufacturers to produce lighter yet stronger panels, further improving energy efficiency in construction.

The market for roofing materials has also evolved, driven by increasing consumer awareness of sustainability and energy efficiency. Roof roll forming machines are now capable of producing materials that meet various energy standards, such as cool roofs that reflect sunlight and reduce heat absorption. This shift not only enhances the performance of buildings but also contributes to lower energy bills, making green roofing solutions more appealing to homeowners and commercial builders alike.

Furthermore, the globalization of the construction market has encouraged roof roll forming machine manufacturers to expand their reach. Many companies are now actively exporting their machines to emerging markets, where infrastructure development is on the rise. By providing these markets with high-quality, efficient roofing solutions, manufacturers are contributing to the modernization of construction practices worldwide.

In conclusion, roof roll forming machine manufacturers play a vital role in the construction industry, offering solutions that enhance efficiency, reduce labor costs, and support sustainable building practices. As technology continues to advance and the demand for innovative roofing materials grows, these manufacturers will undoubtedly remain at the forefront of the industry, shaping the future of roofing solutions. Their significance goes beyond just production; they are paving the way for smarter, more sustainable building practices across the globe.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025