roll shutter door forming machine

Understanding Roll Shutter Door Forming Machines A Key to Efficient Production

In today’s fast-paced industrial landscape, the demand for durable and reliable products has never been higher. Among the critical components in the construction and security sectors are roll shutter doors, known for their strength, ease of use, and versatility. Behind the manufacturing of these essential fixtures lies the roll shutter door forming machine, an ingenious piece of machinery that streamlines production processes and enhances productivity.

The Importance of Roll Shutter Doors

Roll shutter doors serve multifunctional roles, often employed in retail environments, warehouses, and garages to provide security. Their design allows for efficient space utilization, as they roll neatly into a compact coil, freeing up overhead space. Additionally, these doors can be constructed from various materials, including aluminum, steel, and vinyl, catering to different needs, whether for aesthetics or security.

What is a Roll Shutter Door Forming Machine?

A roll shutter door forming machine is a specialized piece of equipment that manufactures the metal slats used in roll shutter doors. The machine processes raw metal sheets, shaping and profiling them into the necessary components with precision. This ensures consistency in quality and dimensions, which is crucial for the proper functioning of the finished product.

Key Components of the Forming Machine

The manufacturing process typically involves several stages, facilitated by different components of the machine

1. Feeding Mechanism This initial stage feeds raw materials, usually steel or aluminum coils, into the machine. It ensures an uninterrupted supply of the necessary material for forming.

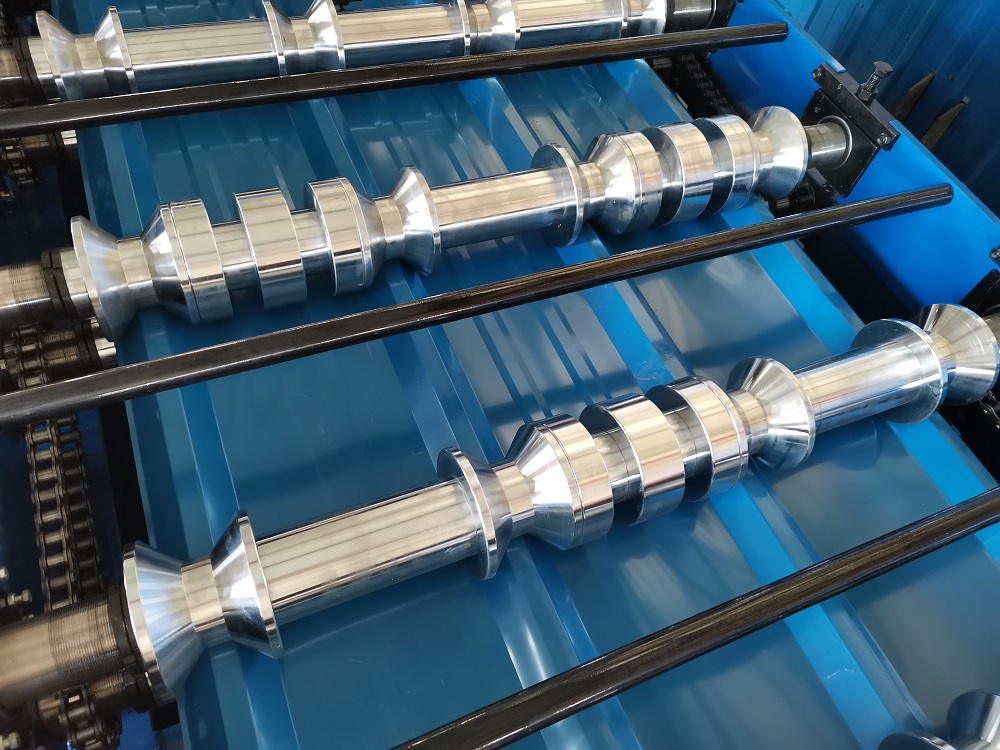

2. Roll Forming Station The heart of the machine, this section utilizes a series of rollers to gradually shape the raw metal into the desired profile. Each roller is designed to guide the material through specific angles, creating a uniform cross-section along the length of the strip.

roll shutter door forming machine

3. Cutting Units After profiling, the formed slats are cut to the required lengths. Automation in this stage minimizes waste and maximizes efficiency, enabling high production rates.

4. Control Systems Modern roll shutter door forming machines incorporate advanced automation and control systems. These systems allow for precise adjustments and monitoring throughout the production process, ensuring high quality and reducing human error.

Benefits of Using Roll Shutter Door Forming Machines

- Efficiency The automation of the forming process significantly reduces production time compared to manual methods. This capability is essential for meeting high-demand scenarios.

- Consistency and Quality Automated machinery guarantees uniformity in the produced components, resulting in high-quality roll shutter doors that meet strict safety standards.

- Flexibility Many roll shutter door forming machines can be adjusted to produce various door profiles. This flexibility allows manufacturers to cater to diverse market needs without investing heavily in new machinery.

- Cost-Effectiveness Although the initial investment in a roll shutter door forming machine may be substantial, the long-term savings through reduced labor costs and increased efficiency can be profound.

Conclusion

In conclusion, the roll shutter door forming machine is a vital component in the production chain of roll shutter doors. Its ability to create reliable, consistent, and high-quality products is unparalleled, making it indispensable for manufacturers looking to thrive in a competitive market. As technology continues to advance, these machines will undoubtedly evolve, incorporating even more features that enhance productivity and quality. For businesses that recognize the importance of efficiency and quality, investing in a roll shutter door forming machine is a strategic step towards sustaining growth and success in the industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025