rolling shutter profile making machine

Understanding the Rolling Shutter Profile Making Machine

In the realm of modern manufacturing, automation and precision engineering play crucial roles in enhancing product quality and production efficiency. One of the fascinating innovations in this domain is the rolling shutter profile making machine. This specialized equipment is designed to produce rolling shutter profiles, which are essential components in security and comfort for both residential and commercial establishments.

What is a Rolling Shutter?

Before diving into the specifics of the machinery, it's important to understand what rolling shutters are. Rolling shutters are made up of horizontal slats or panels that roll up and down to cover openings such as windows or doors. They provide security by preventing unauthorized access, help in managing light and airflow, and offer thermal insulation. Given their increasing popularity, there's a growing demand for efficient manufacturing solutions to produce them.

The Functionality of Rolling Shutter Profile Making Machines

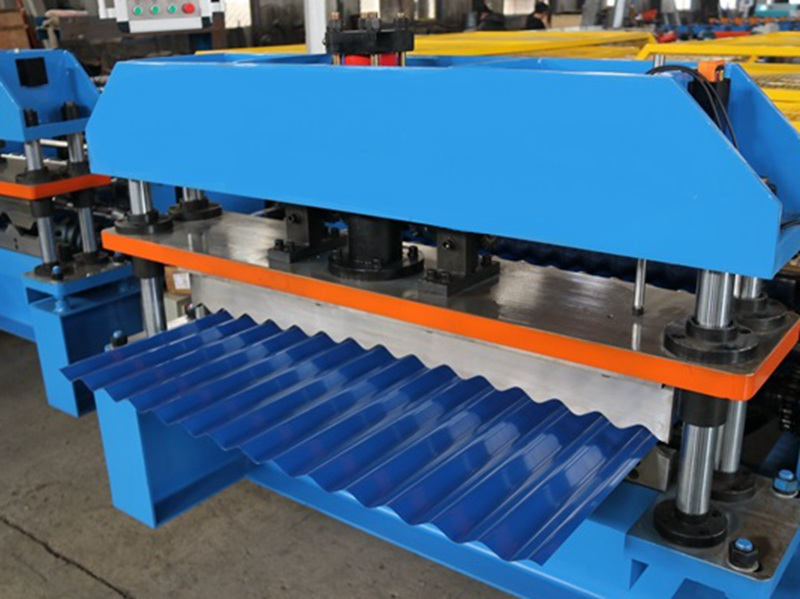

Rolling shutter profile making machines are designed to create the individual slats or profiles from metal coils, typically from materials like aluminum or galvanized steel. These machines automate the process of cutting, bending, and shaping metal into the required profile. A typical machine consists of several key components

1. Feeding System This system ensures that metal coils are fed into the machine with precision and accuracy. Proper feeding is crucial for maintaining consistency in size and shape.

2. Roll Forming Unit This is the heart of the machine. The metal strip is passed through a series of rollers that gradually shape it into the desired profile. Each set of rollers is engineered to bend the metal progressively, ensuring uniformity and reducing waste.

3. Cutting Mechanism After the rolling process, the continuous strip of profile needs to be cut to specific lengths. Most machines employ either a hydraulic or mechanical cutting system, which can be programmed to deliver precise cuts as per the specifications.

4. Control System Modern machines incorporate advanced control systems that allow for real-time monitoring and adjustments. Users can set parameters for speed, temperature, and pressure to ensure optimal production conditions.

5. Safety Features Given the nature of the machinery and the materials involved, safety is paramount. Machines are equipped with various safety features like emergency stop buttons, safety guards, and overload protection systems to ensure safe operation.

rolling shutter profile making machine

Advantages of Using a Rolling Shutter Profile Making Machine

Investing in a rolling shutter profile making machine offers several advantages

- Efficiency Automation reduces the labor intensity of the production process, allowing for higher output in less time.

- Quality The precision of the machine ensures that every profile produced meets the required specifications, enhancing overall product quality.

- Cost-Effectiveness By minimizing waste and reducing production time, manufacturers can lower their overall costs, thereby increasing profitability.

- Flexibility Many machines offer adjustable settings, enabling production of different profile designs and dimensions, catering to diverse market needs.

Market Trends and Innovations

As the construction and security industries evolve, so do the technologies surrounding rolling shutter profile making machines. Manufacturers are focusing on integrating IoT (Internet of Things) solutions that allow for remote monitoring and control of the machinery. Additionally, the advent of AI-driven systems is paving the way for predictive maintenance, greatly reducing downtime and operational costs.

Sustainability has also become a focal point for manufacturers. Environmentally friendly materials and energy-efficient technologies are now being integrated into rolling shutter profile making processes. This not only meets regulatory requirements but also satisfies the growing consumer demand for sustainable products.

Conclusion

The rolling shutter profile making machine is an indispensable tool in modern manufacturing. It exemplifies the convergence of technology and engineering, allowing manufacturers to meet the rising demands for quality and efficiency in rolling shutters. As technology continues to advance, we can expect even more innovative solutions that will further enhance production processes and product offerings in this vital industry sector. Investing in such machines is not just about meeting current demands but also about preparing for a future where automation and sustainability are paramount.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025