Advanced Rolling Shutter Solutions for Efficient Industrial Manufacturing Processes

Understanding Rolling Shutter Forming Machines

Rolling shutter forming machines play a crucial role in the production of rolling shutters, which are widely used for security and convenience in both commercial and residential buildings. With advancements in technology, these machines have evolved to provide high efficiency, precision, and customization options. This article delves into the various aspects of rolling shutter forming machines, their operation, benefits, and applications in the market.

What is a Rolling Shutter Forming Machine?

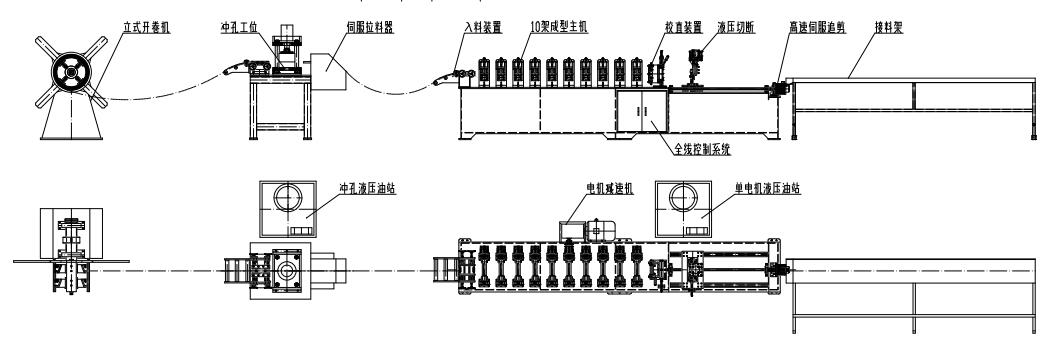

A rolling shutter forming machine is specialized equipment used to manufacture rolling shutters. These machines utilize a series of rollers to shape metal strips, typically made from materials like steel or aluminum, into the slats that comprise the shutter. The machines can produce various profiles, allowing manufacturers to cater to different design requirements and product dimensions.

How Does It Work?

The operation of a rolling shutter forming machine can be broken down into several steps

1. Material Feeding The process begins with feeding a flat metal coil into the machine. The coil is usually pre-treated to prevent rust and enhance adhesion for further coatings.

2. Rolling and Forming As the metal coil passes through a sequence of rollers, it is progressively shaped into the desired profile. The number of rollers may vary depending on the complexity of the shutter design. The machine may also incorporate a cutting mechanism to segment the metal into desired lengths.

3. Curving and Bending Some advanced machines have additional stations for curving and bending the slats, allowing for greater design flexibility and aesthetic appeal.

4. Final Assembly and Inspection Once the slats are formed, they are assembled into complete shutters. Some machines also include features for quality inspections to ensure that the products meet required specifications.

Key Benefits of Rolling Shutter Forming Machines

1. High Efficiency These machines can produce large volumes of rolling shutters quickly, significantly reducing production time compared to traditional manufacturing methods.

rolling shutter forming machine

2. Customization Manufacturers can easily adjust the machine settings to produce different profiles and sizes. This flexibility allows businesses to respond to specific customer demands.

3. Cost-Effectiveness With automation and reduced labor costs, rolling shutter forming machines can lead to significant savings in manufacturing expenses.

4. Durability The high-quality materials used in conjunction with advanced forming processes ensure that the final products are robust and long-lasting, which is critical for security applications.

5. Safety Features Modern machines are equipped with safety features to protect operators and minimize the risk of accidents during operation.

Applications in the Market

Rolling shutters are widely used in various applications due to their security benefits, thermal insulation, and noise reduction capabilities. Some common uses include

- Commercial Properties Shops and storefronts often utilize rolling shutters as a deterrent against burglary and vandalism. These shutters can be easily integrated into existing architectural designs.

- Industrial Facilities Factories and warehouses employ rolling shutters for both security and to manage access to specific areas. They can protect sensitive equipment and inventory from theft or damage.

- Residential Buildings Homeowners are increasingly using rolling shutters for added security, light control, and energy efficiency. They can be deployed on windows and balconies to improve comfort and reduce heating or cooling costs.

Conclusion

Rolling shutter forming machines are pivotal in meeting the growing demand for secure and functional rolling shutters. Their efficiency, versatility, and cost-effectiveness make them invaluable in the production process. As the industry continues to evolve, advancements in technology will further enhance the capabilities of these machines, offering even more options for customization and production efficiency. Understanding these machines' functions and benefits can help manufacturers thrive in a competitive market while meeting consumer expectations for quality and security.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025