rolling shutter strip making machine factory

The Manufacturing Process of Rolling Shutter Strip Making Machines

In today's fast-paced industrial environment, the demand for efficient and high-quality manufacturing equipment is paramount. Among these essentials is the rolling shutter strip making machine, increasingly recognized for its role in producing rolling shutter strips used in various applications, including commercial and residential properties. This article delves into the intricacies of these machines and the processes involved in their production.

Rolling shutter strips are vital for providing security and insulation for buildings. The manufacturing of these strips requires precision and reliability, making the choice of machinery critical. A dedicated factory for rolling shutter strip making machines typically consists of several key components designed to optimize productivity and quality.

The heart of the factory is the production line, where advanced technology meets innovative engineering. A well-established factory usually employs Computer Numerical Control (CNC) technology, allowing for precise cuts and bends in the metal strips used to produce rolling shutters. This automation significantly increases efficiency while minimizing the risk of human error, leading to a higher quality end product.

Another critical aspect of the manufacturing process is the selection of materials

. Typically, high-quality steel or aluminum is used for rolling shutter strips, offering durability and lightweight properties. Factories ensure they source their materials from reputable suppliers, maintaining a consistent standard in their production processes.rolling shutter strip making machine factory

Once the raw materials are received, they undergo rigorous quality control checks. This step is essential, as any defects in the materials can affect the overall performance of the finished product. The machinery used for cutting, bending, and shaping these materials must also be regularly maintained and calibrated to ensure accuracy and longevity.

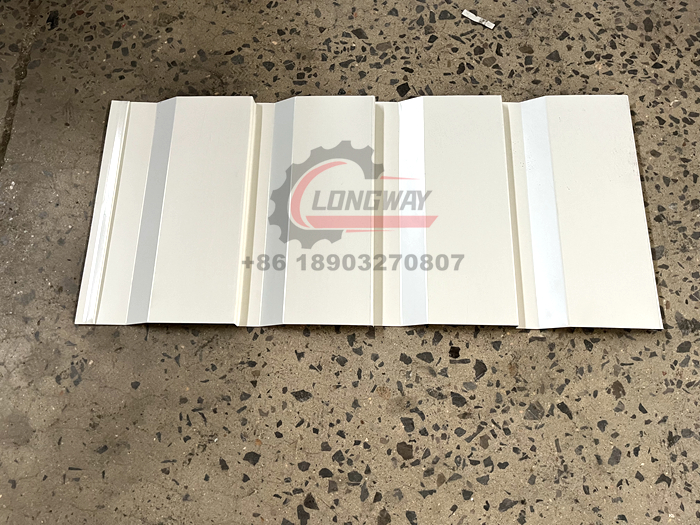

The actual production process involves several stages. Initially, sheets of metal are fed into the rolling shutter strip making machine, where they are cut to the required length. The next phase involves the profiling machine, which shapes the edges of the strips, giving them their characteristic design. Finally, a rolling process forms the strip into a final product ready for assembly.

A significant benefit of having a dedicated rolling shutter strip making machine factory is the ability to customize products according to client specifications. Many factories offer bespoke solutions, allowing customers to tailor dimensions, designs, and finishes to meet specific requirements.

In addition to production capabilities, customer service plays a crucial role in the success of these factories. Establishing a robust communication channel with clients ensures that expectations are met, and any issues are addressed promptly. Many factories also provide after-sales support, including installation assistance and maintenance services, fostering long-term partnerships with their clients.

As the construction and security industries continue to evolve, the demand for rolling shutter strips and their manufacturing machines is expected to grow. Investing in a reliable rolling shutter strip making machine factory can yield significant rewards, combining efficiency, quality, and innovation to meet the ever-changing needs of the market. In conclusion, these factories are not just producers of metal strips; they are integral players in enhancing the safety and functionality of modern buildings.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025