roll forming suppliers companies

The Role of Roll Forming Suppliers in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, the efficiency and precision of production processes are paramount. One such process, roll forming, has gained significant traction due to its ability to produce complex shapes with minimal waste. Central to this process are roll forming suppliers, who provide the necessary machinery, materials, and technical expertise. This article explores the significance of roll forming suppliers and their impact on various industries.

What is Roll Forming?

Roll forming is a continuous bending operation where a long strip of metal is fed through a series of rollers to progressively shape it into a desired cross-section. This manufacturing technique is particularly beneficial for producing long lengths of uniform profiles, such as channels, angles, and other complex shapes. Commonly used materials include steel, aluminum, and sometimes plastics, all of which can be tailored to specific applications.

The Importance of Roll Forming Suppliers

Roll forming suppliers play a critical role in the manufacturing supply chain. They provide not only the machinery required for the process but also the raw materials and the expertise needed to optimize production. Here are several key areas where their contributions are particularly valuable

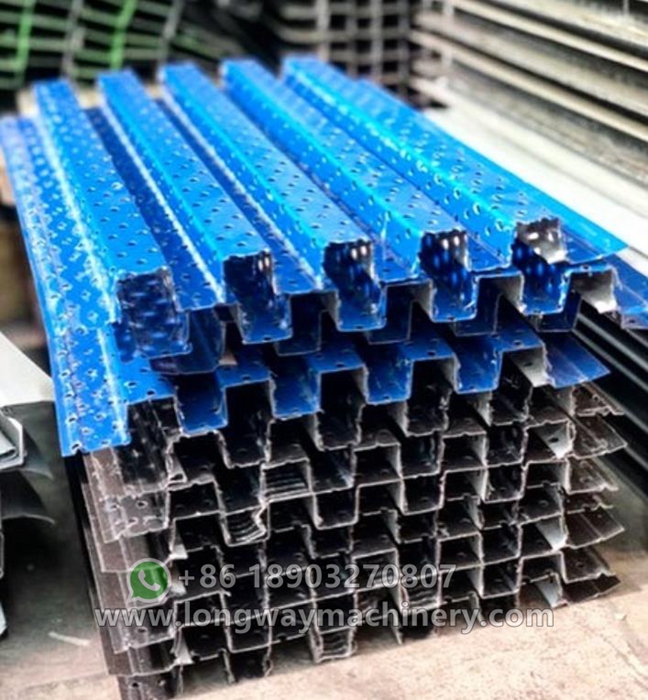

1. Machinery and Equipment Supplier companies specialize in designing and manufacturing roll forming equipment that caters to various production needs. This includes standard and custom roll forming machines that can handle different material types and thicknesses, ensuring that manufacturers achieve the desired profiles efficiently.

roll forming suppliers companies

2. Material Supply A reliable supply of quality raw materials is essential in roll forming. Suppliers often offer a range of materials, including hot-rolled and cold-rolled steel, galvanized sheets, and aluminum. By providing high-quality materials, roll forming suppliers help ensure that the end products meet industry standards and customer specifications.

3. Technical Support and Expertise The complexity of roll forming processes necessitates a certain level of expertise. Suppliers often provide technical support to manufacturers, helping them optimize their production methods. This can include advice on tooling, die design, and process optimization, which ultimately result in better product quality and reduced operational costs.

4. Flexibility and Customization The diverse needs of modern manufacturing require suppliers to be adaptable. Many roll forming suppliers offer customizable solutions to meet specific industry demands. Whether it’s producing specialized profiles for automotive parts or customized components for the construction industry, suppliers work closely with manufacturers to develop tailored solutions.

5. Sustainability Efforts In response to the growing concern about environmental impact, many roll forming suppliers are adopting sustainable practices. This includes sourcing recycled materials, reducing waste during the production process, and utilizing energy-efficient machinery. By integrating sustainability into their operations, these suppliers not only enhance their own market position but also help their clients achieve their environmental goals.

Conclusion

As industries strive for greater efficiency and sustainability, the role of roll forming suppliers becomes increasingly crucial. They are not just vendors of machines and materials; they are partners in innovation and productivity. The expertise and support they provide enable manufacturers to streamline their operations, reduce waste, and improve product quality. With the growing demand for precise and versatile manufacturing solutions, roll forming suppliers will continue to be essential players in the manufacturing ecosystem. Through collaboration and innovation, these suppliers can help shape the future of various industries, reaffirming the importance of their contribution to modern manufacturing practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025