roll forming steel factory

The Evolution of Roll Forming in Steel Manufacturing

Roll forming technology has revolutionized the way steel products are manufactured, providing efficiency and precision that are critical in today's competitive markets. A roll forming steel factory specializes in this unique process, which involves the continuous bending of long strips of metal at room temperature. This article will explore the fundamentals of roll forming, its advantages, and the various applications in the steel industry.

Understanding Roll Forming

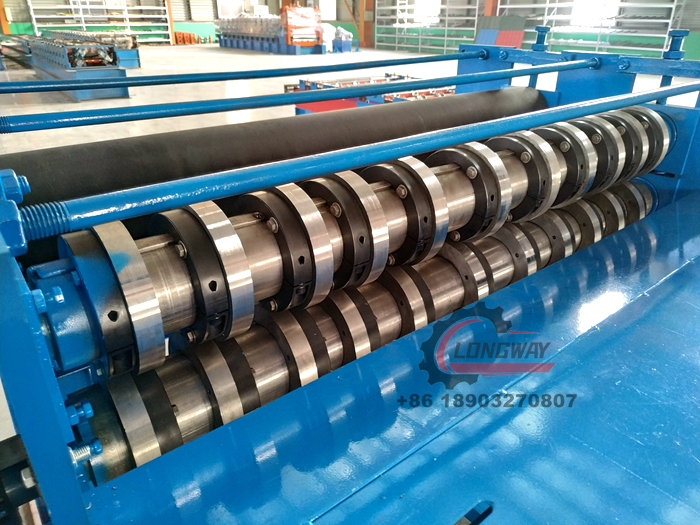

The roll forming process starts with a flat strip of steel, which is fed through a series of specially designed rollers. As the strip passes through this sequence of rollers, it undergoes a gradual bending process. Each pair of rollers is designed to shape the steel to a certain degree, and by the time it exits the last roller, the flat strip has been transformed into a complex profile.

The equipment used in roll forming includes precision rollers, a feed mechanism, and often, a cut-off mechanism at the end of the line. The technology can accommodate a variety of materials, although steel is the most commonly used due to its strength and versatility. Roll forming is particularly advantageous for producing large quantities of identical cross-sectional shapes, making it ideal for mass production.

Advantages of Roll Forming

One of the most significant advantages of roll forming over other manufacturing techniques, such as stamping or forging, is its ability to produce long lengths of continuous product. This characteristic reduces waste as there are minimal off-cuts generated during the process. Furthermore, the use of lightweight materials like steel results in lower shipping costs and easier handling.

Roll forming also offers superior dimensional accuracy. The process allows for tight tolerances that are essential in industries requiring high precision, such as automotive and construction. Additionally, the ability to produce complex shapes without the need for extensive tooling increases flexibility in design, allowing manufacturers to quickly adapt to changing market demands.

roll forming steel factory

Another key benefit of roll forming is its efficiency. The process is continuous, meaning that it can operate at high speeds, which significantly reduces production times. This efficiency, combined with the reduced material waste, makes roll forming one of the most cost-effective methods for metal fabrication.

Applications in Various Industries

A roll forming steel factory plays a critical role in several sectors. In the construction industry, roll-formed steel is often used in the production of elements such as roofing panels, wall frames, and structural components. Its lightweight yet strong properties make it ideal for building applications where strength-to-weight ratios are crucial.

The automotive industry also heavily relies on roll-formed products for components like chassis, bumpers, and door frames. The precision offered by roll forming allows automobile manufacturers to enhance safety and performance features while simultaneously reducing overall production costs.

In the renewable energy sector, roll-formed steel is used in the manufacturing of solar panel frames and wind turbine structures. Given the increasing demand for sustainable energy solutions, the significance of roll forming in supporting green technologies cannot be overstated.

Conclusion

As a cornerstone of modern metal fabrication, roll forming technology continues to evolve, integrating advanced techniques and materials to meet the ever-changing demands of various industries. A roll forming steel factory not only embodies the principles of efficiency and precision but also reflects the commitment to sustainability and innovation in manufacturing practices. With its numerous applications and advantages, roll forming is set to remain at the forefront of steel production, paving the way for a more efficient and sustainable future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025