Mar . 06, 2025 17:59

Back to list

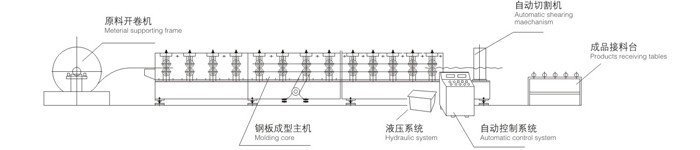

roll forming machine with hole punching

Innovative advancements in manufacturing and materials engineering have given rise to the versatile and efficient roll forming machines with hole punching capabilities. These machines are revolutionizing the way industries approach metal forming and customization, becoming indispensable assets in sectors ranging from automotive to construction. With an emphasis on Experience, Expertise, Authoritativeness, and Trustworthiness, this article delves into the unique features and benefits of these machines, establishing their importance and reliability in modern manufacturing processes.

Moreover, the role of digital technology cannot be overstated when discussing modern roll forming machines. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) systems allows for real-time monitoring and optimization of the forming and punching processes. Through data-driven insights, manufacturers can achieve unprecedented levels of efficiency and make informed decisions that enhance productivity and product quality. Sustainability is another critical consideration where roll forming machines with hole punching capabilities demonstrate their value. By efficiently using materials and minimizing waste, these machines align with global initiatives to reduce industrial carbon footprints. Additionally, their ability to rapidly adapt to new materials and design innovations supports the development of eco-friendly products, appealing to environmentally conscious consumers and businesses. Customer testimonials and case studies further authenticate the benefits of these machines. Industry leaders frequently report significant improvements in production capabilities and market competitiveness after integrating roll forming machines with hole punching functionalities into their operations. The ability to innovate with speed and precision opens new possibilities for design and production, ultimately providing a competitive edge in fast-paced markets. In conclusion, roll forming machines with hole punching capabilities exemplify a pivotal advancement in manufacturing technology. Through a combination of expertise, authority, and reliability, these machines facilitate precision, efficiency, and sustainability. As industries continue to evolve and demand increases for customized, high-quality metal components, the importance of investing in such advanced machinery becomes ever more apparent. For companies aiming to elevate their production capabilities and remain at the forefront of innovation, embracing these dynamic machines is not just an option—it is a strategic imperative for sustained success.

Moreover, the role of digital technology cannot be overstated when discussing modern roll forming machines. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) systems allows for real-time monitoring and optimization of the forming and punching processes. Through data-driven insights, manufacturers can achieve unprecedented levels of efficiency and make informed decisions that enhance productivity and product quality. Sustainability is another critical consideration where roll forming machines with hole punching capabilities demonstrate their value. By efficiently using materials and minimizing waste, these machines align with global initiatives to reduce industrial carbon footprints. Additionally, their ability to rapidly adapt to new materials and design innovations supports the development of eco-friendly products, appealing to environmentally conscious consumers and businesses. Customer testimonials and case studies further authenticate the benefits of these machines. Industry leaders frequently report significant improvements in production capabilities and market competitiveness after integrating roll forming machines with hole punching functionalities into their operations. The ability to innovate with speed and precision opens new possibilities for design and production, ultimately providing a competitive edge in fast-paced markets. In conclusion, roll forming machines with hole punching capabilities exemplify a pivotal advancement in manufacturing technology. Through a combination of expertise, authority, and reliability, these machines facilitate precision, efficiency, and sustainability. As industries continue to evolve and demand increases for customized, high-quality metal components, the importance of investing in such advanced machinery becomes ever more apparent. For companies aiming to elevate their production capabilities and remain at the forefront of innovation, embracing these dynamic machines is not just an option—it is a strategic imperative for sustained success.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products