Leading Companies in Roll Forming Machine Manufacturing for Your Production Needs

The Evolution of Roll Forming Machine Manufacturers Meeting Industry Demands

In today's rapidly evolving manufacturing landscape, the role of roll forming machine manufacturers has become increasingly significant. These specialized companies design and produce machinery that transforms metal sheets into various shapes through a continuous bending process. With applications spanning construction, automotive, and various industrial sectors, the demand for efficient, high-quality roll forming machines continues to rise.

Understanding Roll Forming Technology

Roll forming is a method where metal sheets are passed through a series of rollers that steadily shape the material into specific cross-sections. This process is particularly valued for its ability to produce long lengths of uniform shapes with minimal waste. Roll forming machines are capable of creating complex profiles, making them indispensable in producing components such as metal studs, roofing panels, and gutters.

Historically, the technology has evolved significantly. Early roll forming machines were manual, requiring a high degree of operator skill and oversight. With advancements in technology and materials science, modern manufacturers have integrated automation, computer numerical control (CNC), and sophisticated software into their machines. This not only enhances precision and consistency but also increases production speed and reduces labor costs.

Key Players in the Industry

The market for roll forming machines is diverse, with several manufacturers emerging as leaders. Established companies have honed their expertise over decades, consistently innovating to meet the changing needs of the industry. These manufacturers are equipped to handle a wide range of materials, including steel, aluminum, and even exotic metals, adapting to various customer requirements.

Some prominent roll forming machine manufacturers offer customizable solutions, allowing clients to design machine specifications that meet their specific production needs. This level of flexibility is essential in industries where customization and rapid changeovers are crucial.

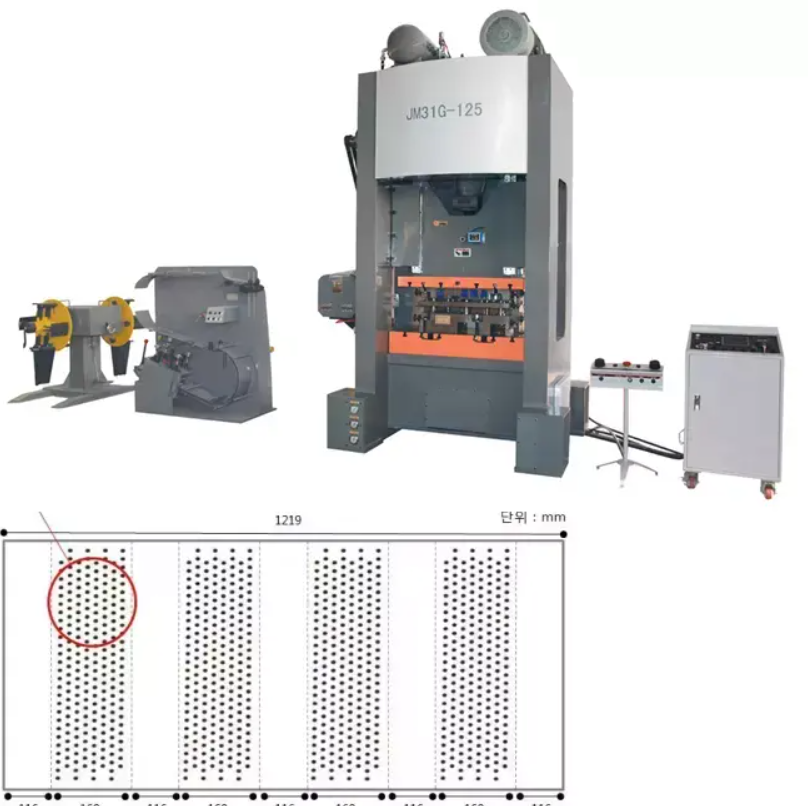

roll forming machine manufacturers company

Quality and Efficiency Central Tenets

Quality and efficiency are paramount in the roll forming machine sector. Manufacturers must adhere to stringent industry standards to ensure their machines can withstand the rigors of continuous operation. Innovations in material selection, machine design, and control systems have drastically improved the durability and efficiency of roll forming machines.

Furthermore, many manufacturers are now incorporating Industry 4.0 technologies, enabling real-time data collection and analysis. This empowers operators to monitor machine performance and make adjustments on-the-fly, leading to less downtime and higher output. Such integration not only enhances productivity but also allows companies to stay competitive in an increasingly globalized market.

Sustainability in Manufacturing

As with many industries, sustainability is becoming a key focus for roll forming machine manufacturers. The push for greener production methods has led to innovations that minimize waste, energy consumption, and carbon footprints. Many manufacturers are now developing machines that optimize material usage, reduce scrap rates, and utilize energy-efficient components. This commitment to sustainability is crucial for meeting both regulatory requirements and consumer expectations in an eco-conscious marketplace.

Conclusion

The landscape of roll forming machine manufacturers is vibrant and continually evolving. These companies are at the forefront of technological advancements, driving efficiency, quality, and sustainability in manufacturing processes. As industries continue to grow and diversify, the demand for innovative roll forming solutions will only increase. Thus, the role of these manufacturers will remain indispensable in shaping the future of metalworking industries worldwide. Whether through automation, customization, or sustainable practices, roll forming machine manufacturers are poised to meet the challenges of tomorrow's manufacturing challenges.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025