Leading Manufacturers of Roll Forming Machines for Efficient Production Solutions

The Evolution and Importance of Roll Forming Machine Manufacturers

In the heart of modern manufacturing, roll forming machines play an essential role in shaping metal materials for various industries, including automotive, construction, and electronics. These machines utilize a continuous bending operation to form long lengths of metal into desired shapes, enhancing production efficiency and precision. As industries evolve and demands increase, the significance of roll forming machine manufacturers cannot be overstated. This article explores the characteristics, technological advancements, and the competitive landscape of roll forming machine manufacturers.

Understanding Roll Forming Machines

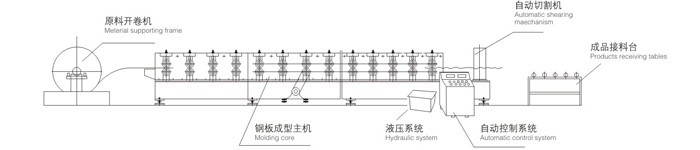

Roll forming is a metal forming process that involves passing a strip of metal through a series of rollers to gradually shape it into a specific profile. This method offers several advantages over traditional metal forming processes, including enhanced material utilization, reduced waste, and high-speed production capabilities. Roll forming machines are commonly used to produce various profiles, such as metal studs, tracks, roofs, and automotive components.

Manufacturers of roll forming machines must design a versatile product that can accommodate different materials, thicknesses, and profiles, meeting the diverse needs of their clients. The engineering precision and technological expertise required in developing these machines are significant, making reliable manufacturers invaluable partners for businesses looking to invest in roll forming technology.

Technological Advancements

Over the years, roll forming machines have undergone significant technological advancements. Innovations in automation, control systems, and materials have revolutionized the capabilities of these machines. The integration of Computer Numerical Control (CNC) technology allows for precise adjustments and consistent product quality, minimizing human error and maximizing efficiency.

Additionally, advancements in software have enabled manufacturers to simulate the roll forming process before actual production begins. This capability allows for better design optimization and helps in identifying potential issues early in the development phase, saving time and resources.

Another notable advancement is the use of high-strength materials, which enables manufacturers to produce lighter and more durable products. This shift is particularly relevant in the automotive industry, where there is a growing demand for lighter components that do not compromise safety or performance.

The Competitive Landscape

roll forming machine manufacturers company

The roll forming machine manufacturing industry is characterized by a mix of established companies and new entrants. Key players in the market have invested heavily in research and development to stay ahead of technological trends and consumer demands. These manufacturers often emphasize customer service, offering tailored solutions to meet specific operational needs.

However, the market is not without its challenges. Increasing global competition and rising material costs can pressure manufacturers to maintain competitive pricing while ensuring high quality. Furthermore, with the push towards sustainable manufacturing practices, roll forming machine manufacturers must also consider environmentally friendly solutions. This includes energy-efficient machines and the ability to process recyclable materials effectively.

Selecting a Reliable Manufacturer

For businesses seeking to invest in roll forming technology, choosing the right manufacturer is crucial. Prospective buyers should consider several factors, including

1. Experience and Reputation Look for manufacturers with a proven track record in the industry. Reviews, testimonials, and case studies can provide insight into their reliability and product quality.

2. Customization Capabilities Not all projects are the same; therefore, a manufacturer should offer customization options to meet specific production requirements.

3. After-sales Support A reliable manufacturer will provide robust after-sales support, including installation, maintenance, and training services to ensure optimum operation of the machines.

4. Technological Innovations Manufacturers that invest in the latest technologies are likely to provide more efficient, effective, and scalable solutions.

Conclusion

As industries continue to grow and evolve, the role of roll forming machine manufacturers becomes increasingly vital. The combination of technological advancements and a focus on customer needs has positioned these manufacturers at the forefront of metal manufacturing. By understanding the significance of these machines and the manufacturers behind them, businesses can make informed decisions that enhance their production capabilities and drive future growth. As the demand for efficient and precise metal forming processes rises, the importance of choosing a reliable roll forming machine manufacturer will only become more paramount.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025